For Texas-based industries like Energy, Manufacturing, and Agriculture, water is a mission-critical operational asset. Its availability and reliability directly impact production, supply chain continuity, and profitability. Given the state's climate—marked by prolonged droughts and punctuated by intense, extreme weather events—strategic water asset management is no longer an optional initiative. It is a core business imperative for mitigating operational risk.

Why Water Is a Critical Operational Asset for Texas Industries

For decision-makers in sectors like Energy & Petrochemical, Manufacturing, and Construction, water must be viewed through a strategic lens to preempt significant operational disruptions. A burst pipe, a contaminated well, or a pump failure is not merely a maintenance issue; it's a direct threat to production schedules, supply chain integrity, and the bottom line.

The reactive approach—addressing water-related problems as they occur—is both inefficient and costly. Proactive management is the only way to ensure operational continuity. This requires a framework for systematically monitoring, maintaining, and optimizing your entire water infrastructure to withstand Texas's unique climate challenges.

Shifting from Expense to Strategic Asset

Viewing water as a core operational asset fundamentally changes risk management. It moves a company beyond simply paying utility bills and performing scheduled maintenance toward a comprehensive strategy that protects the asset's value and ensures its availability during critical periods.

This strategic shift is built on three key pillars:

- Understanding Infrastructure Health: Gaining a precise, data-driven understanding of the condition and performance of every pump, pipe, and storage tank in your system.

- Quantifying Failure Risk: Identifying which assets are most likely to fail and, more importantly, quantifying the operational and financial impact of that failure.

- Optimizing Lifecycle Costs: Planning for repairs and replacements based on data and risk analysis, not waiting for a catastrophic—and budget-breaking—failure to dictate your actions.

A robust water asset management plan transforms a potential liability into a competitive advantage. It ensures that when operations are tested by extreme weather—whether drought or flood—your water systems are resilient enough to withstand the pressure.

The Growing Importance of Water Infrastructure

This focus on water resilience is a global priority. Investment in the water sector is surging, with a recent report showing that 96% of respondents plan to maintain or increase their investments.

This growth highlights the sector's critical role in addressing global challenges, with 15% of global investors deploying over US$1 billion into this area. More insights on capital allocation in the global water sector are available at whitecase.com.

For Texas businesses, this trend reinforces a clear message: securing water infrastructure is non-negotiable for long-term operational viability. The state’s climate volatility makes this even more pressing, as a single flash flood can halt operations. Explore more facts about flooding and its business impact in our detailed guide.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided in this article is for educational purposes only and should not be interpreted as financial advice.

Building Your Water Asset Management Framework

An effective water asset management strategy is a disciplined, forward-looking approach that provides a clear, data-driven view of your entire water infrastructure. For Texas industries, where water security can be compromised by a single weather event, such a framework is essential for operational survival.

This is analogous to managing a mission-critical fleet of vehicles. You would not wait for a breakdown. Instead, you would know the condition of every vehicle, understand route-specific risks, and maintain a solid financial plan for maintenance, fuel, and eventual replacement. The same logic must be applied to water systems.

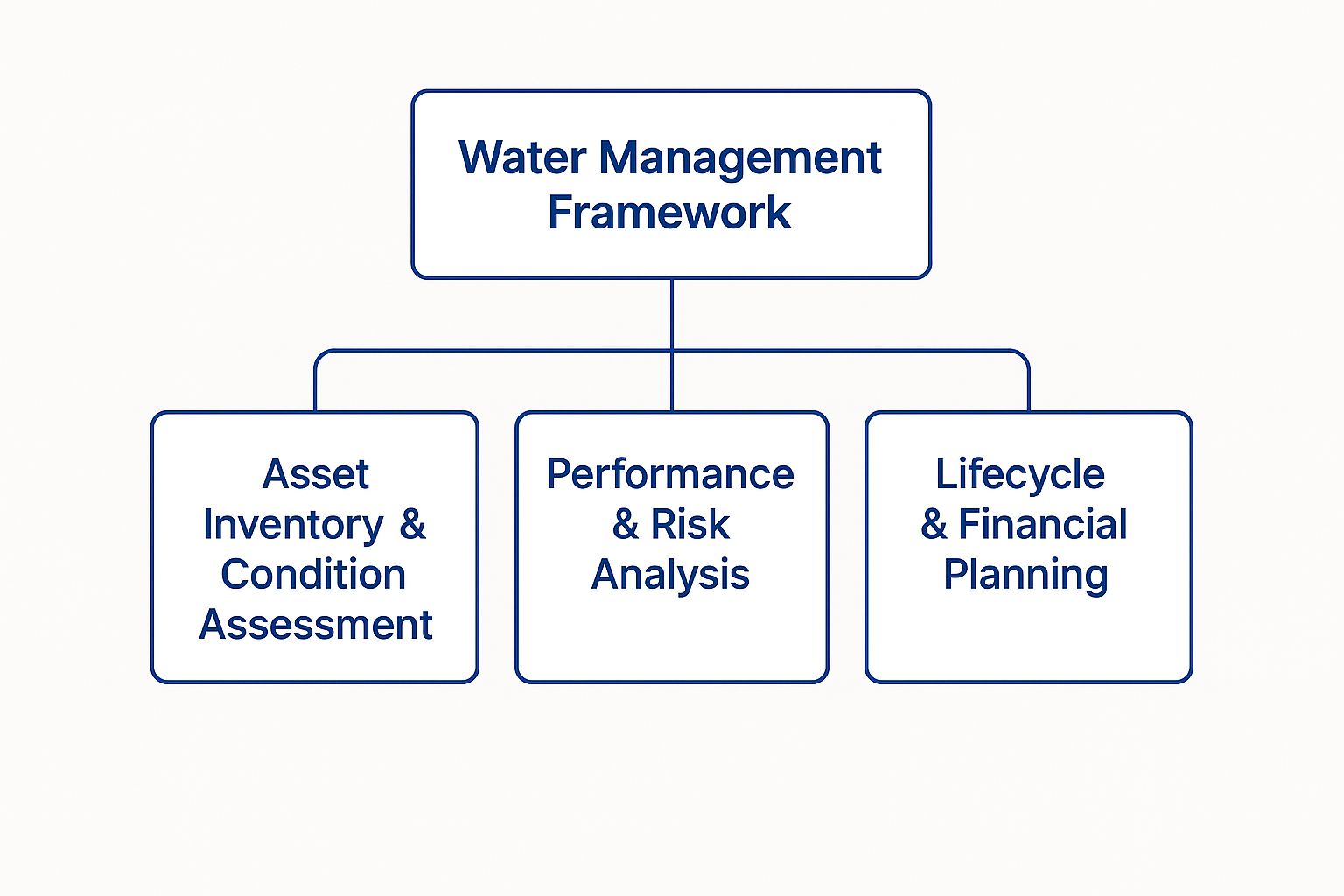

The following infographic illustrates how the three core pillars of this approach work in concert.

These pillars are not independent; they create a continuous improvement loop that strengthens defenses against water-related operational disruptions.

The table below breaks down these pillars and their practical implications for businesses operating in Texas.

Pillars of Water Asset Management for Texas Industries

| Pillar | Objective | Key Activities | Business Impact in Texas |

|---|---|---|---|

| Asset Inventory | Know what you have and what condition it’s in. | Catalog every pump, pipe, tank, and valve. Document age, material, and maintenance history. Map locations. | Prevents surprise failures during peak demand, like a pump giving out during a summer heatwave, protecting production schedules. |

| Risk Analysis | Understand which failures hurt the most. | Analyze the likelihood and consequence of each asset failing. Prioritize assets based on their criticality to operations. | Focuses capital on protecting high-value processes, like ensuring cooling towers at a petrochemical plant have redundant systems to avoid a costly shutdown. |

| Financial Planning | Plan for repairs and replacements—don’t just react. | Forecast long-term capital needs based on asset lifecycles. Create a proactive, multi-year budget for maintenance and upgrades. | Turns unpredictable emergency spending into a planned, manageable operational expense, improving financial stability and investor confidence. |

By systematically building out each of these pillars, you create a comprehensive management system that directly supports operational and financial goals, making your business more resilient to Texas's unique water challenges.

Pillar 1: Asset Inventory and Condition Assessment

You cannot manage what you do not measure. An effective water management program begins with a complete, detailed inventory of every component in your water system.

This is more than a simple list of assets. It is a dynamic record that includes both "vertical" assets—pumps, tanks, treatment equipment—and the "horizontal" assets connecting them, such as pipelines and valves. For each piece of equipment, document the following:

- Asset Details: Type, age, material, manufacturer, and capacity.

- Location: Precise mapping to visualize its role within your facility's network.

- Condition: An objective grade based on physical inspections, performance data analysis, and maintenance logs.

This detailed registry becomes the single source of truth, forming the foundation for all subsequent risk analysis and financial planning.

Pillar 2: Performance and Risk Analysis

Once you know what you have, the next step is to understand its operational significance. This pillar connects the physical condition of your assets to tangible business risk.

The primary question to answer is: "If this asset fails, what are the operational and financial consequences for our business?"

To determine this, you must evaluate two critical factors:

- Likelihood of Failure: What are the odds that a specific asset will fail? This is calculated based on its age, condition, and operational stress. An older pump running at 95% capacity during a Texas heatwave presents a much higher risk than a new pump under normal load.

- Consequence of Failure: If it fails, what is the severity of the impact? A broken irrigation pipe in a non-critical area is an inconvenience. A failed cooling tower pump at a petrochemical plant could trigger a multi-million-dollar shutdown and pose a significant safety risk.

By mapping the likelihood and consequence of failure for every key asset, you can objectively identify which components demand immediate attention, ensuring that capital and resources are allocated to mitigate the most significant threats to your operations.

Pillar 3: Lifecycle and Financial Planning

The final pillar translates risk analysis into a strategic, long-term financial plan. It shifts the organization from scrambling to fund emergency repairs to proactively planning and funding asset replacements.

By viewing water infrastructure as a managed portfolio, Texas businesses can shift from reactive spending to strategic capital investment. This approach improves financial predictability and ensures that critical systems are reliable when they are needed most.

This involves treating your water infrastructure not as a recurring expense but as a portfolio of valuable assets with predictable lifecycles.

You can begin to forecast future capital needs based on the expected useful life of equipment and established risk priorities. For instance, if data indicates a critical water pump has approximately five years of reliable service remaining, its replacement can be budgeted for over time, eliminating sudden, unbudgeted capital expenditures.

This strategic approach is a cornerstone of a comprehensive business resilience framework, ensuring the long-term health and dependability of your essential water systems.

Using Technology for Smarter Water Decisions

Effective water asset management today requires moving beyond spreadsheets and periodic manual checks. For Texas businesses, digital tools now provide the data-driven insights needed to make proactive decisions that protect the bottom line and enhance operational resilience.

These technologies transform abstract risks into manageable data points. Instead of reacting after a pipeline bursts, you receive an alert before it fails. Instead of guessing where infrastructure is most vulnerable, you can visualize it on a map.

This is a significant global shift. The digital water market is expanding rapidly, with over 2,191 providers worldwide. This growth is a direct response to the increasing pressures of aging infrastructure and climate change, making these tools essential for any operation seeking to mitigate risk. You can get a closer look at this evolving landscape from Bluefield Research.

The Power of Real-Time Monitoring with IoT

The Internet of Things (IoT) provides a nervous system for your water infrastructure, feeding live data from critical points across your network.

Consider a petrochemical plant in Texas with miles of cooling water pipelines. By deploying smart sensors along these lines, operators can track minute changes in pressure, flow, and temperature. The moment a potential leak is detected, an alert is triggered. This early warning can mean the difference between a minor repair and a costly shutdown or environmental incident.

By leveraging real-time data, companies can shift from scheduled maintenance to condition-based maintenance. This means resources are allocated precisely when and where they are needed, optimizing costs and dramatically reducing the risk of unexpected failures.

Predictive Analytics for Proactive Maintenance

While IoT sensors provide real-time status, predictive analytics forecast what is likely to happen next. This technology uses historical data, machine learning, and real-time inputs to predict equipment failures before they occur.

For a large agricultural operation in West Texas dependent on a network of irrigation pumps, a predictive model can analyze data on motor vibration, power consumption, and run hours to flag a pump showing early signs of wear. This allows the maintenance team to schedule a repair during a planned downtime, avoiding a catastrophic failure during a critical growing season. Integrating hyper-local weather data can further enhance the accuracy of these forecasts.

Visualizing Risk with GIS Mapping

Geographic Information System (GIS) technology offers a powerful way to visualize and manage your entire water network. It layers critical asset data onto a detailed map, showing how your infrastructure interacts with its physical environment.

For a logistics hub near the Texas Gulf Coast, GIS is indispensable for managing flood risk. The facility can map its entire water system—from storm drains to retention ponds—and overlay that data with FEMA flood maps and storm surge models. Combining this with advanced tools like Drones and GIS provides an even more robust picture for analysis. This allows decision-makers to:

- Identify Vulnerabilities: Pinpoint which assets are most exposed to flooding.

- Model Scenarios: Simulate the impact of a hurricane on drainage systems.

- Prioritize Investments: Allocate capital to harden the most critical and at-risk components.

This spatial awareness transforms complex risk data into an actionable visual plan, enabling smarter, more targeted investments in resilience.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided in this article is for educational purposes only and should not be interpreted as financial advice.

How to Implement a Risk-Based Approach

With limited capital and competing operational demands, the central question for any Texas business leader is: where should we invest to achieve the greatest impact? A risk-based approach to water asset management provides the answer. It ensures that resources are allocated precisely to protect the most critical infrastructure and maintain operational continuity.

This approach requires evaluating assets not just by their age or condition but by the potential consequences of their failure.

For a manufacturing plant, a small leak in a non-essential pipe is a nuisance. However, the failure of a primary cooling tower pump is a catastrophic event that could halt production for days. A risk-based framework provides the data to differentiate between these scenarios and direct capital toward mitigating the risks that truly threaten the bottom line.

Identifying Your Most Critical Assets

The first step is to establish a clear hierarchy of your water assets based on their operational importance. This involves mapping your entire process flow and identifying the specific pipes, pumps, and tanks that support each critical function.

For every component, ask the fundamental question: "What would happen to our business if this asset failed?"

The goal is to identify assets whose failure would trigger the most severe consequences, such as:

- Operational Shutdowns: Assets directly tied to core business activities, like the water treatment systems at a petrochemical facility.

- Supply Chain Disruptions: Infrastructure that supports logistics, such as the drainage systems at a distribution hub. Failure could lead to flooded loading docks and halted shipments.

- Regulatory Fines: Components required for compliance, such as wastewater discharge monitoring equipment.

- Safety Hazards: Systems that prevent dangerous conditions, like fire suppression water tanks.

This analysis allows you to build a "criticality matrix" that ranks every asset, providing a clear roadmap for focusing attention and resources.

Calculating the Business Risk Score

Once critical assets are identified, the next step is to quantify their individual risk. In this context, business risk is determined by a simple but powerful formula that combines two key factors for each asset: the probability of its failure and the severity of the consequences.

Business Risk = Likelihood of Failure x Consequence of Failure

This calculation transforms abstract concerns into a tangible score that can be used to prioritize investments. An asset with a low consequence and low likelihood of failure receives a low score. An asset with a high consequence and high likelihood of failure becomes an immediate priority.

An aging pump (high likelihood of failure) essential for the main production line (high consequence of failure) would receive a top-tier risk score. Conversely, a newer, redundant pump (low likelihood) in a secondary process (low consequence) would rank much lower. This scoring system provides an objective, data-driven method for allocating maintenance and capital improvement budgets. For a deeper analysis of this process, review our guide on effective risk assessment methodologies.

Case Study: A Texas Logistics Hub in a Flood Zone

A major logistics hub near Houston, located in a flood-prone area, recognized that a severe storm posed a significant threat but lacked a clear plan for investing in resilience upgrades.

Using a risk-based approach, the company began by mapping its entire water infrastructure, including storm drains, culverts, retention ponds, and sump pumps. They then analyzed historical rainfall data and local flood maps to assess the likelihood of failure for each component during a major storm event.

Next, they evaluated the consequence of failure. A blocked culvert in a remote parking area was a low-consequence issue. However, the failure of the main drainage system around the loading docks was identified as a catastrophic risk that could flood the facility, destroy inventory, and halt shipments for weeks.

This high-risk drainage system became their top priority. They invested in reinforcing culverts, upgrading pump capacity, and installing real-time water level sensors. When a tropical storm later impacted the area, the upgraded system performed as designed, preventing a supply chain disruption that would have resulted in millions in lost revenue and recovery costs. This targeted investment, driven by a clear risk assessment, protected the core of their operation.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided in this article is for educational purposes only and should not be interpreted as financial advice.

Navigating Texas Water Regulations

For any business operating in Texas, a sound water asset management plan must extend beyond monitoring pumps and pipes to include navigating the state's complex regulatory landscape.

Failure to integrate compliance into your framework can lead to significant fines, operational shutdowns, and reputational damage.

Success requires understanding the decentralized nature of Texas's water authority, where power is distributed among state agencies, influential river authorities, and hundreds of local districts. This structure makes a proactive compliance strategy essential for uninterrupted operations.

Understanding Key Regulatory Bodies

The first step is to identify the primary entities influencing your water rights and usage. For most industrial, agricultural, and construction operations, several organizations are particularly important.

Texas Water Development Board (TWDB): The TWDB functions as the state's high-level water strategist. While it typically does not issue permits directly to businesses, its statewide water plans and drought classifications shape regional policies that directly affect industrial facilities.

Groundwater Conservation Districts (GCDs): With over 100 districts across Texas, GCDs are powerful local bodies that regulate groundwater. They issue drilling permits, establish pumping limits, and enforce drought response plans.

If your business relies on groundwater, your local GCD is the single most important regulatory body you will engage with. Its rules directly govern your water allocation and mandate cutbacks during drought conditions.

The Impact on Your Business Operations

These regulations create tangible operational requirements. For many businesses, a mandatory Drought Contingency Plan is a prime example. This is not a static document but an active playbook detailing precisely how your facility will reduce water consumption during declared drought stages. Failure to have or follow this plan can result in steep penalties.

A financial perspective is also crucial. For over a decade, investment firms have identified water as a critical resource, creating specialized funds to secure water quality and availability. The performance of these funds signals a clear trend: investors are increasingly focused on water for both financial return and environmental responsibility. More information on strategic water investment is available at waterinv.com.

Integrating regulatory compliance into your water asset management strategy is non-negotiable. It protects your business from legal penalties and ensures your "license to operate" by demonstrating responsible stewardship of a shared public resource.

Compliance as a Risk Mitigation Tool

It is essential to view compliance not as a burden but as a strategic risk management tool. Understanding local permitting rules upfront can prevent costly delays on a new construction project. Similarly, staying ahead of potential drought restrictions allows a manufacturing plant to secure alternative water sources or implement conservation technology before a crisis occurs.

This proactive approach also applies to flood risk—another major regulatory concern in many parts of Texas. Local and federal rules often dictate how facilities in flood-prone areas must be constructed and protected. Integrating these requirements into your operational plan is fundamental to resilience. You can explore this topic further in our guide on flood zone mapping for Texas facilities.

By treating regulations as a blueprint for resilient design rather than a hurdle, businesses can build stronger, more defensible operations.

From Plan to Action: Making Water Management Work

Understanding the principles of proactive water asset management is one thing—implementing them is another. For Texas businesses in Energy, Manufacturing, or Agriculture, this is a direct investment in long-term resilience. The next step is to translate these concepts into concrete action.

This must be a business-wide initiative, not a task siloed within the maintenance department. The first step is to assemble a cross-functional team, including operations personnel who understand on-the-ground realities, finance experts who can track costs and ROI, and risk managers to connect the effort to broader business objectives. Their primary mandate is to champion the shift from reactive, expensive repairs to strategic, data-driven planning.

Start Small, Win Big: The Pilot Project

With a team in place, avoid attempting to audit every water asset simultaneously. This can lead to analysis paralysis. Instead, select one high-impact area for a pilot project. This allows you to demonstrate value quickly and build a compelling case for expanding the program.

For a manufacturing plant, this might be the cooling tower system, where a failure could halt production instantly. For a logistics hub, it could be the primary stormwater drainage network that protects loading docks from flooding. The key is to choose an area where failure is costly and success is measurable.

A well-executed pilot project achieves three critical objectives:

- It proves the ROI. You generate hard data demonstrating how the approach reduces emergency repair costs and prevents downtime.

- It refines your process. The team learns what works on a small scale before a full-scale rollout.

- It builds momentum. A tangible success is the most effective way to secure buy-in from leadership and other departments.

Building Your Resilience, Step by Step

This focused approach—assemble the right team, conduct a high-level audit of critical assets, and execute a targeted pilot—provides a clear path forward. It transforms the complex concept of water asset management into an achievable process that delivers immediate value.

To further develop your strategy, our guides on developing a business resilience framework and understanding flood zone mapping for Texas facilities are valuable next steps.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided in this article is for educational purposes only and should not be interpreted as financial advice or an insurance recommendation. Our goal is to equip Texas business leaders with data-driven insights to make informed decisions about operational risk.

Still Have Questions?

Implementing a full-scale water asset management strategy can seem daunting, especially for Texas businesses in capital-intensive sectors like Energy, Manufacturing, and Agriculture. We understand. Practical questions about where to begin, how this differs from current practices, and what defines success are common. Here are answers to questions we frequently hear from business leaders.

Where Do We Even Start if We Have Limited Resources?

With a limited budget, the most effective first step is a risk-based assessment. This is not a comprehensive audit but a targeted analysis to identify the specific water assets whose failure would inflict the most severe operational or financial damage on your business.

Focus your initial resources on assessing the condition and performance of only those high-priority assets. This ensures that your limited capital is allocated where it can have the greatest impact on reducing operational risk. A small-scale pilot project on a single critical system is also an excellent way to prove ROI and build the business case for a broader program.

How Is This Different from Our Regular Maintenance?

Think of it this way: regular maintenance is often reactive or based on a fixed schedule, such as changing a vehicle's oil every 5,000 miles, regardless of operating conditions. Water asset management is a proactive, holistic strategy.

It uses data on an asset's condition, performance, and failure risk to optimize both maintenance activities and long-term capital planning. Instead of merely fixing pumps when they break, this approach helps you predict and prevent failures, manage lifecycle costs, and directly link the performance of your water infrastructure to your company's financial health.

The core difference is the shift from a cost-based, reactive mindset to a strategic, data-driven one. Asset management turns maintenance from an unpredictable expense into a calculated investment in operational resilience and long-term stability.

What Key Metrics Should We Track to Know if This is Working?

Success in water asset management can be measured through a combination of operational, financial, and risk-based metrics. Tracking the right key performance indicators (KPIs) provides clear evidence of the program's value.

- Operational Metrics: Look for tangible improvements, such as a measurable reduction in water loss from leaks, fewer unplanned equipment shutdowns, and increased water use efficiency.

- Financial Metrics: Success is reflected in lower emergency repair costs, predictable and optimized capital expenditures, and a decrease in fines related to regulatory non-compliance.

- Risk Metrics: From a strategic perspective, success means a quantifiable reduction in both the probability and the potential financial impact of a water-related operational disruption, demonstrating that your company is becoming more resilient.

At ClimateRiskNow, we provide Texas businesses with the critical risk intelligence needed to protect their most valuable assets from extreme weather. Our Sentinel Shield assessments deliver location-specific insights, helping you quantify your exposure to events like flooding, hurricanes, and freezes. We translate complex climate data into a clear, actionable strategy to safeguard your operations.

Request a demo to see how Sentinel Shield can fortify your business resilience.