Having effective emergency evacuation procedures is not a compliance exercise—it's a core component of operational risk management. For business leaders in Texas, these procedures are the documented, systematic playbook for safely moving personnel away from immediate danger during extreme weather events, chemical spills, or fires.

For Texas industries such as Energy & Petrochemical, Manufacturing, and Logistics, a generic plan is insufficient. A robust strategy must be documented and tailored for specific threats, from Gulf Coast hurricanes to inland industrial accidents, ensuring a rapid, orderly, and life-saving response when a crisis hits.

Building Your Facility's Evacuation Blueprint: A Guide for Decision-Makers

For executives in Texas's key industrial sectors, an evacuation plan is a fundamental operational safeguard. An effective strategy moves beyond generic checklists and is customized to the specific threats your facility faces, whether it's a hurricane storm surge along the Gulf Coast or a chemical release in an industrial corridor. Viewing your evacuation strategy as a core element of business continuity is a direct investment in protecting personnel, assets, and operational stability.

The financial stakes of inadequate preparation are significant. The National Centers for Environmental Information (NCEI) reports that Texas has experienced 175 billion-dollar disaster events since 1980, the highest of any state. These figures underscore the necessity of robust emergency evacuation procedures within a comprehensive disaster risk reduction framework.

Disclaimer: ClimateRiskNow provides data and insights for educational and risk management purposes only and does not sell insurance or financial products. The information in this article should not be interpreted as financial advice or an insurance recommendation.

The Pillars of a Resilient Plan

A successful evacuation blueprint is built on several core pillars, with each element working in concert to create a comprehensive and practical system. The goal is to empower your team to act decisively when every second is critical.

These pillars form the foundation of a plan that can withstand the immense pressure of a real-world emergency. The table below breaks down the essential components that should form the backbone of your industrial evacuation plan.

Core Components of an Industrial Evacuation Plan

| Pillar | Objective | Key Actions for Texas Businesses |

|---|---|---|

| Comprehensive Risk Assessment | Identify facility-specific threats | Analyze vulnerabilities to storm surges in Houston, tornadoes in DFW, or chemical releases near industrial corridors. |

| Clear Communication Protocols | Ensure alerts reach all on-site personnel | Implement multi-layered systems (sirens, text alerts, PA systems) to notify employees, contractors, and visitors, including backups for system failures. |

| Practical, Realistic Training | Build procedural muscle memory and confidence | Conduct hands-on drills and full-scale simulations that mimic real-world scenarios, identifying weaknesses before an actual event. |

| Continuous Improvement | Maintain a living, relevant document | Schedule regular reviews and tests; update the plan to reflect changes in facility layout, personnel, or operational hazards. |

Each pillar is critical. A plan with a strong risk assessment but poor communication protocols will fail just as surely as one with inadequate training.

Frame your evacuation plan not as a regulatory requirement, but as a cornerstone of operational resilience. This proactive mindset is what separates businesses that survive disruption from those that don't.

Conducting a Texas-Specific Risk Assessment

An effective evacuation plan begins with a data-driven risk assessment. For any Texas facility, this requires moving beyond generic templates to analyze the specific threats tied to your precise location and daily operations. A petrochemical facility on the Houston Ship Channel faces a fundamentally different risk profile than a manufacturing plant in Dallas-Fort Worth.

By proactively identifying potential disasters, you can address vulnerabilities before a crisis occurs. This transforms your plan from a compliance document into a practical, life-saving operational tool.

Identifying Location-Based Threats

Texas's vast and diverse geography presents a wide range of natural hazards. Your first step is to identify which are most relevant to your specific operational footprint.

Consider these regional risk factors:

- Gulf Coast Facilities (Houston, Corpus Christi): Primary threats include hurricane storm surges, high-velocity winds, and catastrophic flooding. A risk assessment must map all low-lying areas of your property and evaluate the structural integrity of buildings against a Category 4 or 5 storm.

- North Texas Operations (Dallas-Fort Worth): Located in "Tornado Alley," these facilities must prepare for sudden, violent tornadoes, large hail, and intense thunderstorms that can cause flash floods and widespread power outages.

- West Texas and Panhandle Sites (Midland, Amarillo): Risks here include fast-moving wildfires, extreme heat waves that stress equipment and personnel, and rapid temperature drops ("blue northers") that can halt operations with little warning.

Mapping these external threats is the first step toward understanding their potential impact on your people, equipment, and critical infrastructure. For more on this, explore the full scope of disaster risk reduction from the United Nations.

The purpose of a risk assessment is not to perfectly predict the future, but to prepare for probable scenarios. A clear understanding of your unique threats allows you to allocate resources effectively and build a plan that addresses your most significant vulnerabilities first.

Analyzing Operational and Facility-Specific Hazards

Beyond weather, your industrial processes introduce another layer of risk. These internal hazards can trigger an evacuation or complicate a weather-driven one. A thorough internal review means identifying potential failure points and mapping hazardous materials.

A lumber mill's primary internal threat is a rapidly spreading fire, demanding wide, clear evacuation routes. A chemical plant must focus on toxic gas releases, with plans contingent on wind direction and requiring specialized PPE.

Your assessment should produce a detailed inventory of site-specific risks:

- Hazardous Materials: Pinpoint the exact location, quantity, and type of all chemical, flammable, or explosive materials on site.

- Vulnerable Infrastructure: Identify critical systems—electrical substations, control rooms, data centers—and assess their failure modes during an emergency.

- Equipment Failure Points: Determine which machinery could overheat, rupture, or fail under stress, creating a secondary hazard.

The need for this level of detail is growing. The Internal Displacement Monitoring Centre reported over 7 million new disaster-related displacements in the Americas in 2023 alone. These figures are a clear signal that robust emergency plans are non-negotiable. You can read the full report on global displacement trends to grasp the full scale of the issue.

This comprehensive risk profile becomes the blueprint for an evacuation procedure that is genuinely tailored, relevant, and actionable for your Texas operation.

Designing and Documenting Your Evacuation Plan

After completing a thorough risk assessment, the next step is to translate those findings into a clear, actionable, and documented evacuation plan. This document is your operational blueprint for a crisis. It must be simple enough for anyone to understand under extreme stress, yet detailed enough to meet Occupational Safety and Health Administration (OSHA) standards.

For Texas industries, this is a practical guide that must account for everything from a sudden chemical release in a petrochemical plant to a flash flood warning at a construction site.

Establishing a Clear Chain of Command

In an emergency, ambiguity leads to chaos. A well-defined chain of command ensures rapid, authoritative decision-making. Your plan must name a designated coordinator—and backups—with the full authority to order an evacuation without hesitation.

Additionally, assigning specific roles creates a network of responsibility, ensuring all critical tasks are covered:

- Floor Wardens: Responsible for sweeping assigned areas and confirming all personnel have evacuated. In a large manufacturing plant, this may require one warden per production line.

- Medical First Responders: Team members trained in first aid and CPR provide critical immediate assistance before professional emergency services arrive.

- Shutdown Specialists: Designated and trained personnel must execute critical equipment shutdown procedures. In the Energy and Manufacturing sectors, this step is vital to prevent cascading failures.

Mapping Routes and Assembly Points

Clear, well-marked evacuation routes are the difference between order and panic. Your plan must visually map primary and secondary escape paths from every area of your facility. A secondary route is a critical backup for when a primary path is blocked by fire, smoke, or debris.

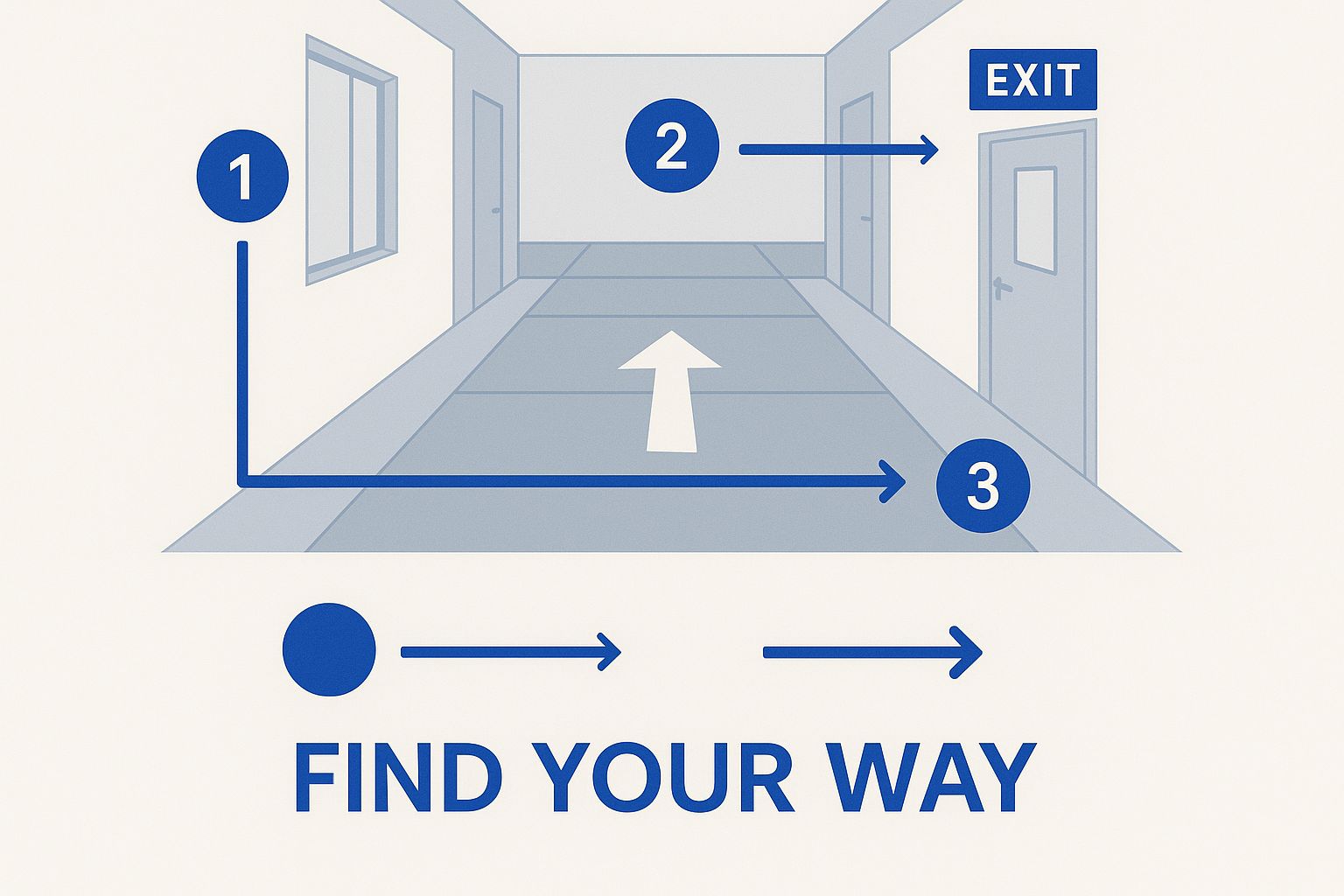

Visual aids are incredibly powerful in this context.

As shown, successful plans rely on simple, unambiguous guidance that personnel can follow instinctively under pressure.

Equally important are designated assembly points. Both a primary and an alternate must be chosen strategically, located a safe distance from the building to protect personnel from potential fire, explosions, or structural collapse. For a logistics warehouse, this means being clear of truck traffic; for an agricultural processing facility, it means being upwind from potential ammonia leaks.

An evacuation plan is only as strong as its weakest link. A blocked exit, an unsafe assembly point, or an unclear command structure can cause a well-intentioned procedure to fail when it's needed most.

Creating a System for Personnel Accountability

Knowing who is safe and who may still be inside is a critical function of any evacuation. Your plan must include a robust system for accounting for every person on-site, including employees, contractors, and visitors.

A simple but effective method is to maintain an accurate sign-in/sign-out log at all entry points. During an evacuation, this log becomes the primary roster for headcounts at the assembly point. Floor wardens should report to the central coordinator with a list of everyone accounted for from their zone.

Consider this case: A North Texas manufacturing facility received a sudden tornado warning. The shift supervisor used a digital roster on a tablet to quickly confirm that all 52 employees and three visiting contractors had reached the designated storm shelter. This immediate accountability allowed them to provide first responders with precise information, confirming no search and rescue was needed inside the main building.

The final, documented plan must be easily accessible to all employees and reviewed regularly. This is the foundational text for all training drills, ensuring that when an alarm sounds, everyone knows precisely what to do.

Implementing a Resilient Communication System

An emergency evacuation plan is only as effective as its ability to reach every person on site. When primary systems fail during a severe weather event, your communication strategy becomes a lifeline, standing between orderly action and dangerous confusion.

For sprawling industrial facilities in Texas, a single point of failure is not an option. Relying solely on a fire alarm or mass email is a recipe for disaster. A layered, resilient system is required.

Building a Multi-Channel Alert Network

The objective is to create overlapping layers of communication. This is non-negotiable in noisy, complex environments like a manufacturing floor or a chemical plant. Effective plans integrate several systems:

- Physical Alarms: Loud sirens, horns, and high-intensity strobe lights are essential for cutting through ambient noise on a plant floor.

- Mass Notification Platforms: These services push alerts via text, email, and automated voice calls, reaching office personnel, field workers, and truck drivers on the property.

- Two-Way Radios: When cellular networks are down or overloaded, two-way radios provide a reliable, off-grid communication line for the emergency response team.

- Public Address (PA) Systems: A centralized PA system allows for the delivery of direct, specific instructions that can mitigate panic and guide personnel effectively.

A communication system isn't just about broadcasting an alert. It’s about confirming message receipt and maintaining control of a rapidly evolving situation. The best emergency evacuation procedures are built on a redundant, reliable, and pressure-tested network.

Crafting Unambiguous Emergency Messages

In a crisis, clarity saves lives. Vague instructions cause hesitation when seconds are critical. Develop pre-scripted, fill-in-the-blank templates for your most likely emergency scenarios. A chemical spill requires a different message than a tornado warning.

Templates should be simple and instantly understandable, stating:

- The specific nature of the threat. (e.g., "Tornado Warning Issued for this Facility.")

- The required action. (e.g., "Evacuate Immediately via the East Exits.")

- The designated assembly point. (e.g., "Proceed to Assembly Point C.")

- A clear statement of authenticity. (e.g., "This is NOT a drill.")

Understanding the strengths and weaknesses of each communication channel is key to effective delivery.

Evacuation Communication Channel Comparison

| Communication Channel | Pros | Cons / Limitations | Best For |

|---|---|---|---|

| Sirens / Strobes | Instant, high-impact, cuts through noise. | No detailed information, dependent on power. | Immediate, site-wide alert to grab attention. |

| Mass Notification (SMS/Email) | Reaches individuals directly, can be location-targeted. | Dependent on cell/internet service, potential for delays. | Reaching office staff, remote workers, and providing updates. |

| Two-Way Radios | Highly reliable, works off-grid, allows for two-way comms. | Limited range, requires trained users and charged batteries. | Real-time coordination between emergency response teams. |

| Public Address (PA) System | Delivers clear, live instructions to a wide area. | Vulnerable to power loss, can be hard to hear in loud areas. | Guiding evacuations and dispelling rumors with official info. |

Ensuring System Reliability and Leadership Coordination

All critical communication equipment requires a reliable backup power source, such as an uninterruptible power supply (UPS) for short-term interruptions and a generator for extended outages.

Additionally, establish a solid communication tree for your leadership team. This structure ensures key decision-makers can be reached instantly and can then relay information through their departments, maintaining order and a unified response. These well-defined protocols are a cornerstone of any serious business continuity plan, as detailed in our guide on hurricane preparedness for businesses.

Training Your Team Through Realistic Drills

A documented emergency plan is theoretical until tested. For Texas business leaders, the true measure of a plan is not its detail on paper, but how flawlessly the team executes it under pressure. Realistic, repeated training drills are one of the most effective investments in facility resilience. The goal is to transform written instructions into instinctual action.

Moving Beyond Simple Walk-Throughs

While a basic walk-through is suitable for initial training, pressure-testing a plan requires more complex, realistic scenarios that simulate the friction and confusion of a real event.

A typical progression includes:

- Tabletop Exercises: Leadership and the emergency response team walk through a specific scenario (e.g., a chemical leak during a thunderstorm with primary communications down). This identifies decision-making and communication gaps without disrupting operations.

- Functional Drills: These hands-on drills test a single component of the plan, such as activating the emergency notification system or deploying the first aid team.

- Full-Scale Drills: This comprehensive test simulates a real emergency as closely as possible, involving a complete facility evacuation and potentially coordination with local first responders. This is where unpredictable human factors and logistical hurdles are uncovered.

An untested plan is an unreliable one. The insights from a single, well-designed drill are invaluable for identifying and fixing weak spots in a controlled setting before a real crisis does it for you.

Designing Drills That Uncover Weaknesses

To generate actionable data, drills must target potential weak points by deliberately injecting complications.

Incorporate these variables into training exercises:

- Blocked Evacuation Routes: Unexpectedly block a primary exit to test employee knowledge of secondary routes and the adaptability of floor wardens.

- Communication Delays: Simulate a failure of the main alert system to measure how quickly the team switches to backup communication methods.

- Personnel Accountability Challenges: Run a scenario with an "unaccounted for" individual to test headcount procedures and reporting speed.

For example, a construction site manager in Central Texas could run a drill simulating a flash flood warning where the main equipment exit is suddenly "underwater," testing not just personnel evacuation but also asset-securing protocols under a tight deadline.

The Crucial Role of Post-Drill Feedback

The most valuable part of any drill is the post-event debrief. This is an honest assessment of what went right and, more importantly, what did not. Gather feedback from all participants, as frontline employees often provide the most valuable insights into confusing signage, bottlenecks, or inadequate alarms.

Your post-drill review should answer key questions:

- What was the total time from alarm to final headcount?

- Did any communication channels fail or prove ineffective?

- Were floor wardens able to clear their areas and report back efficiently?

- Did employees know where to go and what to do without confusion?

- What unexpected problems arose during the drill?

Use this data to refine your plan, update training materials, and design the next drill to test the implemented improvements. This continuous cycle of drilling, feedback, and iteration is the hallmark of a prepared organization. This proactive training is a key component of a larger strategy; explore this further in our guide on how to create a disaster recovery plan.

Keeping Your Evacuation Plan Current and Effective

Emergency preparedness is a continuous cycle of review and improvement. A plan developed last year may already be obsolete due to shifts in operations. For Texas industries, where facility layouts and production processes evolve, emergency evacuation procedures must be treated as a living document. This is essential for operational resilience.

The process begins by defining specific events that automatically trigger a full review of your evacuation plan.

Key Triggers for a Plan Review

While an annual audit is a good baseline, some events demand immediate attention to avoid leaving your team vulnerable.

Key triggers include:

- Changes in Facility Layout: Renovations, expansions, or significant equipment relocation can render existing evacuation maps obsolete.

- Introduction of New Hazards: Bringing new chemicals or volatile materials on-site requires an immediate update to your risk assessment and related procedures.

- Lessons from a Drill or Incident: Every drill and real incident provides invaluable data. Use this feedback to pinpoint weaknesses and strengthen the plan.

Your emergency plan must mirror your current operational reality. A static plan creates a false sense of security, which is often more dangerous than having no plan at all.

This commitment to continuous improvement is a core component of a broader strategy. To understand how this integrates into the bigger picture, it is helpful to know what business continuity planning is, as this provides the framework for incorporating evacuation procedures into your company’s overall resilience strategy.

Ultimately, maintaining an effective plan is about ensuring your team can respond with confidence when it matters most, protecting both your people and your operations from preventable harm.

Your Questions Answered

For executives managing facilities in Texas's Energy, Manufacturing, and Logistics sectors, several common questions arise regarding emergency evacuation plans.

How Often Should My Company Conduct Evacuation Drills?

OSHA requires most businesses to conduct a drill at least annually. However, for high-hazard Texas industries like petrochemicals or heavy manufacturing, this is the bare minimum. Best practice suggests quarterly drills for different shifts to ensure universal participation. An annual full-scale, unannounced drill is also recommended to test real-world response under pressure. More frequent drills are necessary after significant facility changes, personnel turnover, or process modifications to maintain procedural muscle memory.

What Are the Most Common Mistakes in Evacuation Planning?

A critical and frequent oversight is failing to plan for employees with disabilities. Other common mistakes include relying on a single exit route, lacking a clear chain of command, using ambiguous language in communications, and not having a clearly designated, safe assembly point. The single biggest mistake, however, is creating a plan and then allowing it to become outdated. An untested, un-reviewed plan is merely a document, not a life-saving procedure.

The best plans are living documents, constantly refined after every drill and post-incident review. In emergency preparedness, stagnation is one of the greatest risks, especially when facing threats as unpredictable as hurricanes and other natural disasters.

How Do We Account for Visitors and Contractors?

Your evacuation plan must cover every individual on your property. This begins with a robust sign-in/sign-out system to maintain an accurate headcount. Upon arrival, visitors and contractors should receive a concise safety briefing covering the basics of your evacuation plan. A best practice is to assign employee or department "hosts" who are responsible for guiding their guests to safety during an alarm, ensuring no one is left behind.

At ClimateRiskNow, we provide Texas businesses with the critical risk intelligence needed to build resilient operations. Our Sentinel Shield assessments deliver location-specific data to help you create effective, actionable emergency plans. Turn complex climate data into a strategic advantage—request a demo at https://www.climaterisknow.com.