For business leaders in Texas, particularly within the Energy, Petrochemical, Manufacturing, Logistics, Agriculture, and Construction sectors, effective hurricane preparedness is no longer a seasonal chore—it is a critical operational imperative and a source of competitive advantage. A well-executed plan does more than protect physical assets and personnel; it safeguards market share, ensures operational continuity, and defends your brand's reputation in an era of increasing climate volatility.

Why Hurricane Preparedness Is a Competitive Differentiator

For decision-makers across Texas, the conversation around extreme weather has fundamentally shifted from reactive checklists to strategic risk management. Proactive planning now separates resilient, thriving companies from those left managing costly downtime and logistical chaos. Businesses that prepare effectively resume operations faster, secure their supply chains, and maintain stakeholder trust while competitors are still assessing damages.

This shift is driven by data. The frequency and intensity of storms are escalating, making historical performance an unreliable predictor of future risk. For instance, early forecasts for the 2024 Atlantic hurricane season from Colorado State University pointed to 23 named storms, 11 hurricanes, and five major hurricanes—numbers that significantly exceed the 30-year average. This heightened activity is tied directly to record-warm Atlantic sea surface temperatures and the influence of La Niña, creating favorable conditions for powerful storm formation. Businesses that delay readiness efforts are accepting greater operational risks and higher recovery costs. You can learn more about specific readiness actions in our detailed guide on how to prepare for hurricane season.

From Liability to Strategic Asset

When viewed through a strategic lens, preparedness ceases to be a cost center and becomes a valuable asset. A well-designed plan provides a clear, actionable framework for protecting your most critical functions.

The core benefits for your operation include:

- Enhanced Operational Resilience: Minimize downtime with clear protocols for securing facilities, protecting vital equipment, and activating backup systems before a storm impacts your area.

- Supply Chain Security: Mitigate disruptions by pre-qualifying alternate suppliers and logistics partners located outside of primary impact zones.

- Strengthened Stakeholder Confidence: Send a clear message to investors, clients, and employees that your organization is managed responsibly and built for long-term resilience.

This guide is a roadmap for Texas executives looking to build a formidable hurricane preparedness plan. It focuses on actionable, data-driven insights tailored to the unique operational realities of the Energy, Petrochemical, Manufacturing, Logistics, Agriculture, and Construction sectors.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided in this article is for educational purposes only and should not be interpreted as financial advice. Our goal is to empower business leaders with the data and insights needed to make informed risk management decisions.

By moving beyond generic checklists, you can develop a dynamic strategy that safeguards your assets, protects your people, and solidifies your competitive position. The time to build that resilience is now, before the next storm forms in the Gulf.

Conducting a Data-Driven Hurricane Risk Assessment

A robust hurricane preparedness plan begins with a precise, data-driven assessment of your specific vulnerabilities. For Texas businesses—especially in critical sectors like Energy, Manufacturing, and Construction—this requires a granular analysis tailored to your unique operational footprint. This process is not about listing what could go wrong; it is about building a dynamic risk model that informs strategic resource allocation.

Start with physical assets. For a petrochemical plant on the Gulf Coast, this means stress-testing storage tanks against current wind load standards and evaluating containment system capacity against storm surge models. For a logistics firm, it involves mapping primary and alternate transportation routes to identify flood-prone choke points that could sever supply lines.

Beyond physical structures, you must quantify operational dependencies. How long can your facility operate without grid power? What are the single points of failure in your data and communication infrastructure? A thorough assessment assigns a quantifiable risk to these dependencies, enabling informed decisions about investing in backup generators, redundant data centers, or satellite communications.

Evaluating Key Risk Categories

To develop a complete risk profile, your assessment must focus on three core areas. Each presents distinct challenges and demands specific analysis, ensuring no critical blind spots remain.

- Physical Asset Exposure: This is a detailed inventory of your buildings, heavy machinery, and critical infrastructure. Evaluate the integrity of roofing, windows, and flood barriers. For a construction site, this means securing materials and equipment that could become dangerous projectiles in winds exceeding 100 mph. For an agricultural operation, it’s about understanding the vulnerability of crops, livestock, and irrigation systems to catastrophic flooding and high winds.

- Operational & Supply Chain Dependencies: Map every process essential to your business operations. Identify every critical supplier, logistics partner, and utility service. What is your contingency plan if a key supplier in another hurricane-prone state is disrupted for weeks? How will port closures impact both incoming materials and outgoing products? Answering these questions is fundamental to building a resilient supply chain.

- Human Resource & Communication Risks: Your personnel are your most critical asset. The assessment must account for their safety and ability to perform their duties during a crisis. This involves stress-testing employee communication systems, establishing clear remote work protocols, and ensuring your emergency response team is well-defined and rigorously trained.

Integrating Data for a Dynamic Model

An effective risk assessment is driven by data, not assumptions. The goal is to create a dynamic model of your vulnerabilities that can be updated as forecasts change. This involves layering multiple data sets to create a comprehensive risk landscape. Start with official resources like FEMA flood maps to establish a baseline flood risk. Then, overlay this with historical storm track data from the National Hurricane Center (NHC) to analyze how past events have impacted your specific locations.

For a more forward-looking analysis, business decision-makers can leverage advanced climate risk assessment tools to model future hurricane scenarios with greater precision.

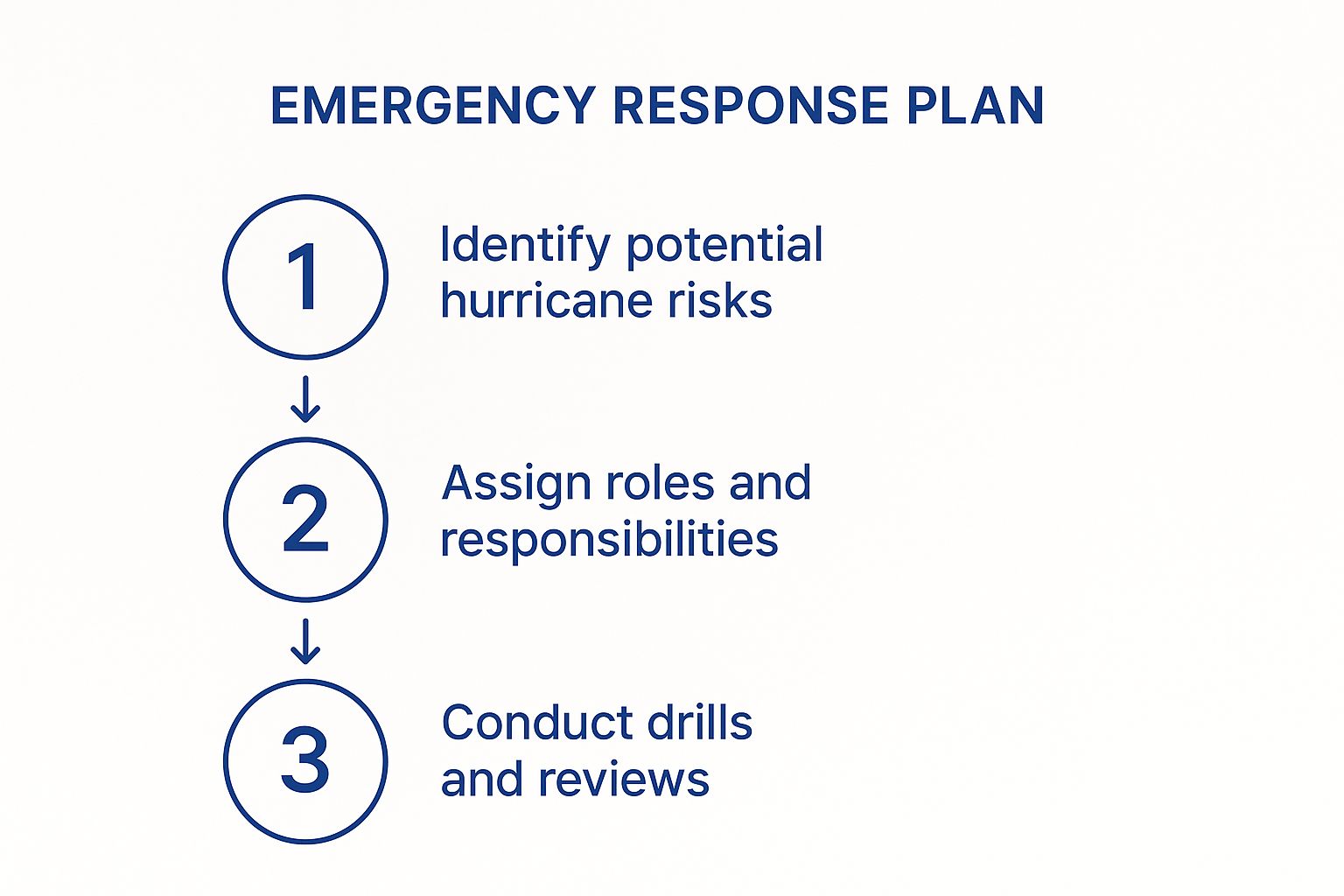

This graphic breaks down the essential workflow for translating risk assessment into an executable plan.

As the visual clarifies, risk identification is the foundational step that informs all subsequent actions.

The necessity for this level of detail is increasing. Global weather patterns are shifting, and the threat from powerful tropical cyclones is expanding. The 2023 Atlantic season, for example, saw 20 named storms, ranking fourth for the most-named storms in a year since 1950. This trend underscores why Texas businesses require agile disaster plans that incorporate real-time weather intelligence.

By systematically identifying and quantifying your risks, you transform hurricane preparedness from a reactive chore into a strategic advantage. This foundational assessment provides the clarity needed to allocate resources effectively, protecting your operations, your people, and your bottom line.

Hurricane Preparedness Checklist For Texas Industries

Because different industries face unique threats, a one-size-fits-all checklist is insufficient. A manufacturing plant's priorities differ from those of a petrochemical facility or a large-scale agricultural operation. The table below outlines high-level actions tailored to the specific risks faced by Texas's core industries before, during, and after a hurricane.

| Phase | Energy & Petrochemical | Manufacturing & Logistics | Agriculture & Construction |

|---|---|---|---|

| Before the Storm | Verify containment systems; secure floating roof tanks; initiate safe shutdown procedures. | Secure inventory; pre-position critical parts; confirm alternate transportation routes. | Secure loose materials & equipment; relocate livestock to higher ground; protect irrigation systems. |

| During the Storm | Monitor tank levels & pressure; maintain skeleton crew in hardened control room; communicate with emergency services. | Monitor facilities for water intrusion via remote sensors; track storm's impact on supply routes. | Monitor livestock & crop conditions remotely where possible; ensure personnel are in safe shelters. |

| After the Storm | Conduct detailed damage assessments of process units & pipelines; manage controlled restarts. | Assess damage to warehouses & transportation hubs; reroute shipments; communicate with customers about delays. | Assess crop & livestock losses; inspect buildings & fences for damage; begin debris cleanup. |

This checklist serves as a starting point. A comprehensive plan will flesh out each of these points with specific procedures, assigned responsibilities, and detailed recovery protocols for your unique operation.

Building a Business Continuity Plan That Works

Once you have quantified your vulnerabilities, the next step is to construct a Business Continuity Plan (BCP) that can withstand a hurricane's impact. This is not a static document to be filed away; it is a dynamic playbook designed to maintain critical functions for your Texas-based business and accelerate post-event recovery. This plan is where your risk assessment becomes concrete action.

At the core of a functional BCP is a precise identification of your most essential business functions—the processes that, if halted, stop revenue generation and damage client relationships. For a Houston-based manufacturer, this might be a specific production line. For a logistics company, it is the dispatch and tracking system. Once these critical functions are defined, you can build protective measures around them.

Identifying Critical Functions and Setting Triggers

Your plan must pinpoint every process, technology platform, and team member vital for delivering your core products or services. This requires a deeper analysis than a simple departmental overview. Who are the key personnel? What specific software is non-negotiable? What machinery is irreplaceable in the short term?

With these functions identified, you must establish clear, unambiguous triggers for activating your BCP. Waiting for landfall is too late.

Effective triggers for a Texas business often include:

- Geographic Triggers: The plan is initiated when a named storm enters the Gulf of Mexico or crosses a specific line of longitude relevant to your operations.

- Intensity Triggers: Different phases of the plan activate as a storm escalates from a tropical storm to a Category 1, 2, or 3+ hurricane.

- Official Alerts: Activation is tied directly to watches or warnings issued by the National Hurricane Center or local authorities, such as the Texas Division of Emergency Management (TDEM), for your operational counties.

Clarity in these triggers prevents hesitation and second-guessing during the critical hours before a storm's arrival.

Data Protection and Remote Operations

In any disaster, data is one of your most valuable and vulnerable assets. A robust BCP must include foolproof data backup and recovery protocols. This means redundant, geographically dispersed backups. Relying solely on an on-site server is a critical oversight. Best practice is a hybrid approach: local backups for rapid recovery from minor issues, combined with cloud or off-site backups in a different geographic region to protect against widespread physical damage.

Simultaneously, you need secure remote work capabilities for essential staff to maintain command and control if your primary facility is inaccessible. A logistics coordinator must be able to manage routes from a safe location, and an energy trader must execute decisions without being physically on a trading floor.

A relevant case study: A Houston-based manufacturing firm maintained operational continuity by pre-staging three weeks of critical inventory at an inland warehouse in Dallas. As the hurricane approached, a designated remote team took over client communications and order management, ensuring minimal disruption to customer service.

Establishing a Clear Communication Chain

A communication vacuum breeds chaos. Your BCP must meticulously outline a chain of command and a multi-layered communication strategy. Who has the authority to make critical decisions? How will those decisions be disseminated to employees, suppliers, and clients?

This demands a communication system that is not dependent on a single point of failure, like local cellular networks, which are often overwhelmed. Redundancy is essential.

- Primary: Mass notification systems that can push text, email, and voice alerts.

- Secondary: A password-protected page on your company website or a dedicated social media account for updates.

- Tertiary: Satellite phones for the core crisis team to ensure communication can be maintained even if all local infrastructure is compromised.

Lessons from past storms demonstrate that inadequate preparedness extends recovery times and inflates costs. Companies without current, tested plans often face prolonged downtime from supply chain breaks and operational shutdowns. True resilience demands weaving hurricane protocols into a broader crisis management framework for faster, clearer decision-making.

For more on building this framework, review our guide on what is business continuity planning.

Securing Your Supply Chain From Disruptions

A hurricane's impact extends far beyond your facility's property line, sending crippling shockwaves through your supply chain. For Texas industries like Energy, Manufacturing, and Agriculture, these disruptions can be operationally devastating. Even if your own facilities are undamaged, a failure at a single key supplier or logistics hub can halt your entire operation. Therefore, an effective hurricane plan must look beyond your own walls to fortify these critical external dependencies.

When Hurricane Harvey made landfall, it shut down regional refineries and slashed U.S. gasoline refining capacity by over 20%, with nationwide consequences. The storm was a stark lesson: businesses located miles inland can be severely impacted by logistical chaos and transportation shutdowns. Your plan must account for these interconnected risks.

Mapping Your Vulnerabilities

The first step is a comprehensive mapping of your supply chain. This goes beyond a simple list of Tier 1 suppliers to uncover hidden dependencies and single points of failure. Where are your critical component manufacturers located? Which specific ports, highways, and rail lines do your logistics partners depend on?

This analysis often reveals surprising vulnerabilities. It is not uncommon for a business to discover that two seemingly independent suppliers both rely on the same raw material provider located in a high-risk coastal area.

A critical mistake many companies make is failing to assess risk beyond direct suppliers. You must evaluate the risk profiles of your suppliers' suppliers (Tier 2 and Tier 3). Uncovering these deeper dependencies is essential for building genuine resilience against a widespread, regional disaster.

Once you have this detailed map, you can assess the specific hurricane risk for each critical node. This allows you to focus resources on prioritizing the partners and routes that pose the greatest threat to your operational continuity. For a deeper dive into this process, explore our guide on supply chain resilience against extreme weather.

Diversification and Contingency Contracts

Relying on a single supplier or carrier, particularly one in a hurricane-prone region, is an unacceptable operational risk. A resilient supply chain strategy is built on intelligent diversification and pre-negotiated contingency plans.

This strategy involves several key actions:

- Geographic Diversification: Actively identify and qualify alternate suppliers in different geographic regions. For a Texas manufacturer, this could mean establishing a relationship with a supplier in the Midwest or Southeast—well outside the primary Gulf Coast storm track.

- Logistics Redundancy: Secure contracts with alternate transportation carriers before a crisis. This should include trucking companies with assets based safely inland and potentially air freight options for high-priority components if ground transport is impassable.

- Strategic Inventory Buffers: While lean inventory is efficient, it is also fragile. Identify critical, hard-to-source components and build a strategic inventory buffer, ideally stored at a secure inland location away from the coast.

A Case Study in Proactive Planning

Consider a large agricultural company in the Rio Grande Valley, whose business model depends on the rapid transport of fresh produce to market via refrigerated trucks. As a major hurricane tracked toward the coast, its operations team activated a pre-existing contingency plan. Days before landfall, they engaged a logistics provider they had already vetted and contracted with in North Texas.

This allowed them to bring in a fleet of refrigerated trucks from the alternate provider before coastal highways became congested with evacuations. While local competitors scrambled to find available transport in a chaotic market, this company had its produce loaded and en route to distribution centers via safe, inland routes. They not only saved their harvest but also captured market share by being a reliable supplier when others could not deliver. This is what proactive planning looks like: transforming a potential disaster into a competitive advantage.

Implementing Smart Mitigation Measures

After mapping your risks and drafting a continuity plan, you must translate strategy into practice. This critical phase involves targeted investments in physical upgrades, technological redundancies, and—most importantly—personnel training. This is not about arbitrary spending; it is about making data-driven investments to lower your operational risk profile.

The first step is to transform your risk assessment into a prioritized budget. Every potential mitigation measure, from reinforcing roofing to procuring backup generators, must be evaluated through a cost-benefit analysis. Frame these upgrades not as expenses, but as direct investments that protect revenue-generating operations. The upfront cost of installing industrial-grade flood barriers at a coastal manufacturing plant, for instance, may seem substantial. However, when compared to the projected losses from weeks of downtime and saltwater-damaged equipment, the investment becomes a clear strategic decision.

Prioritizing Your Mitigation Investments

Not all mitigation efforts are equal. Focus on protecting the critical assets and functions identified during your risk assessment. This discipline ensures every dollar spent delivers the maximum impact on your operational resilience.

Concentrate on a mix of high-impact structural and technological solutions:

- Structural Reinforcements: For facilities in high-wind zones, this includes reinforcing roofing, bracing large bay doors, and installing impact-resistant windows. In flood-prone areas, elevate critical equipment and consider permanent flood walls or berms.

- Power Redundancy: Grid failure during a major hurricane is a high probability. Investing in backup generators properly sized for your essential operations is non-negotiable, especially for petrochemical plants requiring power for safe shutdowns or agricultural businesses needing to maintain cold storage.

- Communication Resilience: Do not depend solely on terrestrial communication networks. Redundant systems, such as satellite phones for your core crisis team, ensure you can maintain command and control even when local infrastructure is down.

A critical lesson from past storms in Texas was the paralyzing effect of communication breakdowns. A plan is only as good as your ability to execute it when primary systems fail. The capacity to coordinate with teams, suppliers, and emergency services is paramount for a swift recovery.

High-Impact, Low-Cost Measures

Beyond major capital expenditures, several highly effective, lower-cost actions can dramatically improve your readiness. These strategies focus on empowering your personnel and leveraging community resources.

Consider implementing these practical measures:

- Intensive Employee Training: Conduct regular, realistic drills simulating different hurricane scenarios. These exercises build muscle memory, expose gaps in your plan, and ensure your team can act decisively under pressure without direct instruction.

- Mutual Aid Agreements: Forge partnerships with other businesses, either locally or in your industry but located in different regions. These agreements can provide access to shared resources like temporary warehouse space, backup equipment, or personnel during post-storm recovery.

- Mastering Emergency Protocols: Ensure your leadership team is familiar with state and local emergency frameworks, such as the protocols from the Texas Division of Emergency Management (TDEM). Knowing who to contact and how to request resources can significantly reduce recovery time.

Ultimately, smart mitigation is a balanced approach, combining physical and technological defenses with a well-rehearsed human response. The lessons learned from the widespread disruption following Hurricane Harvey underscore the necessity of this comprehensive strategy. You can dig deeper into our analysis of the business takeaways from Hurricane Harvey. By thoughtfully implementing these measures, you transform your preparedness plan from a static document into a dynamic shield that protects your assets, people, and bottom line.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided is for educational purposes only and should not be seen as financial advice.

Common Questions About Hurricane Preparedness in Texas

Even with a comprehensive plan, specific questions often arise as business leaders work to refine their strategies. The following addresses some of the most critical questions we receive from executives across Texas industries.

How Often Should We Update Our Hurricane Plan?

Your hurricane plan should be treated as a living document, not a static file. At a minimum, it requires a full review and update annually, ideally before the Atlantic hurricane season begins on June 1st. This ensures the latest information and protocols are current.

However, an annual review is merely the baseline. The plan must be revisited whenever a significant business change occurs, such as:

- Opening a new facility or closing an old one.

- Onboarding a major new supplier or logistics partner.

- Implementing a significant shift in operational processes.

- Changing key personnel on your leadership or crisis response team.

The most valuable updates stem from testing the plan. After every drill, tabletop exercise, or actual weather event, conduct a formal after-action review. Identify what worked, what failed, and what could be improved. Integrate these lessons into the plan immediately to build true, functional resilience.

What Do Industrial Businesses Often Overlook In Planning?

Two areas are consistently overlooked in industrial planning: employee personal preparedness and post-event mental health support. A business continuity plan is ineffective if the personnel required to execute it are unable to do so. If your team members are preoccupied with protecting their own homes and families, they cannot effectively manage critical business functions. Leading companies actively support their employees' personal preparedness by offering resources, guidance, and flexible time off before a storm.

The other significant blind spot is the immense psychological stress a disaster places on a team. The pressure of recovery, dealing with personal losses, and operating in a chaotic environment can lead to burnout and serious mental health challenges. A truly prepared organization plans for this by pre-arranging access to post-event counseling and mental health resources for its staff.

Do Inland Texas Businesses Really Need A Hurricane Plan?

Yes, absolutely. It is a critical error to assume hurricanes are exclusively a coastal threat. A business in Dallas, Austin, or San Antonio may not face storm surge, but it remains exposed to other devastating impacts.

Inland regions are frequently impacted by:

- Catastrophic Inland Flooding: Slow-moving tropical systems can deposit enormous amounts of rainfall hundreds of miles from the coast. Hurricane Harvey, for example, caused devastating riverine and flash flooding that inundated facilities and shut down transportation networks far inland.

- Prolonged Power Outages: Hurricane-force winds can topple major transmission lines deep into the state, causing power outages that last for days or even weeks, resulting in a complete operational shutdown for many businesses.

- Severe Supply Chain Breakdowns: When coastal hubs like the Port of Houston or major arteries like I-10 are compromised, the flow of goods for the entire state is choked. Inland businesses can find themselves cut off from essential materials and unable to ship finished products.

For an inland business, the preparedness plan must be laser-focused on reliable backup power, understanding local flood risks from rivers and creeks, and having pre-arranged contingency logistics plans.

We Have No Formal Plan. What Is The First Step?

If you are starting from zero, the immediate first step is to assign clear ownership. Designate a dedicated leader or assemble a cross-functional team to drive the process. Without clear accountability, progress is unlikely.

Once a leader or team is in place, their first task is to conduct the foundational risk assessment detailed earlier in this guide. You cannot build an effective plan without a quantitative understanding of what you are protecting against. Start by identifying your critical business functions—the processes essential for revenue and customer service. Then, map every asset, person, supplier, and technology required to support those functions. This initial analysis will serve as the roadmap for your entire preparedness strategy.

As a Texas business leader, navigating complex climate risks requires more than a generic plan; it demands precise, data-driven intelligence. ClimateRiskNow provides the actionable insights you need to turn vulnerability into resilience. Our Sentinel Shield assessments deliver location-specific risk profiles for your facilities, quantifying exposure to hurricanes, flooding, and other extreme weather events. Move beyond guesswork and make informed decisions to protect your assets and ensure operational continuity.

Discover how our tailored risk intelligence can fortify your business by exploring a demo of Sentinel Shield.