In aviation, an invisible atmospheric boundary can single-handedly determine whether a critical flight for your business gets off the ground. This one weather metric—the cloud ceiling—often becomes the ultimate go/no-go factor for aviation-dependent operations. For Texas companies relying on air transport, understanding its impact is a crucial component of risk management.

What A Cloud Ceiling Means for Your Operations

For decision-makers in Texas industries like energy, construction, and agriculture, understanding the cloud ceiling isn’t just abstract pilot terminology. It's a fundamental part of managing day-to-day operational risk.

Put simply, the cloud ceiling defines the operational rules for pilots. Under clear skies, pilots can navigate by sight, similar to driving a car on a sunny day. This is flying under Visual Flight Rules (VFR), where pilots rely on seeing the ground and the horizon to fly safely.

When a low cloud layer or fog descends, visual navigation becomes impossible. This is the equivalent of flying under Instrument Flight Rules (IFR). In these conditions, pilots must rely entirely on their aircraft's instruments to navigate. The cloud ceiling determines which set of rules they must follow, and not every pilot or aircraft is equipped for IFR.

The Direct Impact on Business Activities

A low cloud ceiling can bring essential business activities to a halt. This isn't just about inconvenient delays; it translates directly into financial losses and logistical challenges that can disrupt entire supply chains.

A low ceiling can mean:

- Grounded Helicopters: Crucial pipeline inspections in the Permian Basin or aerial surveys over Panhandle farmland are postponed.

- Delayed Cargo: Vital manufacturing parts or construction materials bound for DFW or IAH get stuck on the tarmac, halting production lines and pushing back project deadlines.

- Halted Crew Transport: Specialized crews cannot be shuttled to remote energy sites or construction projects, leading to expensive downtime and idle teams.

This is why a solid grasp of daily weather ceiling forecasts is a non-negotiable part of effective operational risk management.

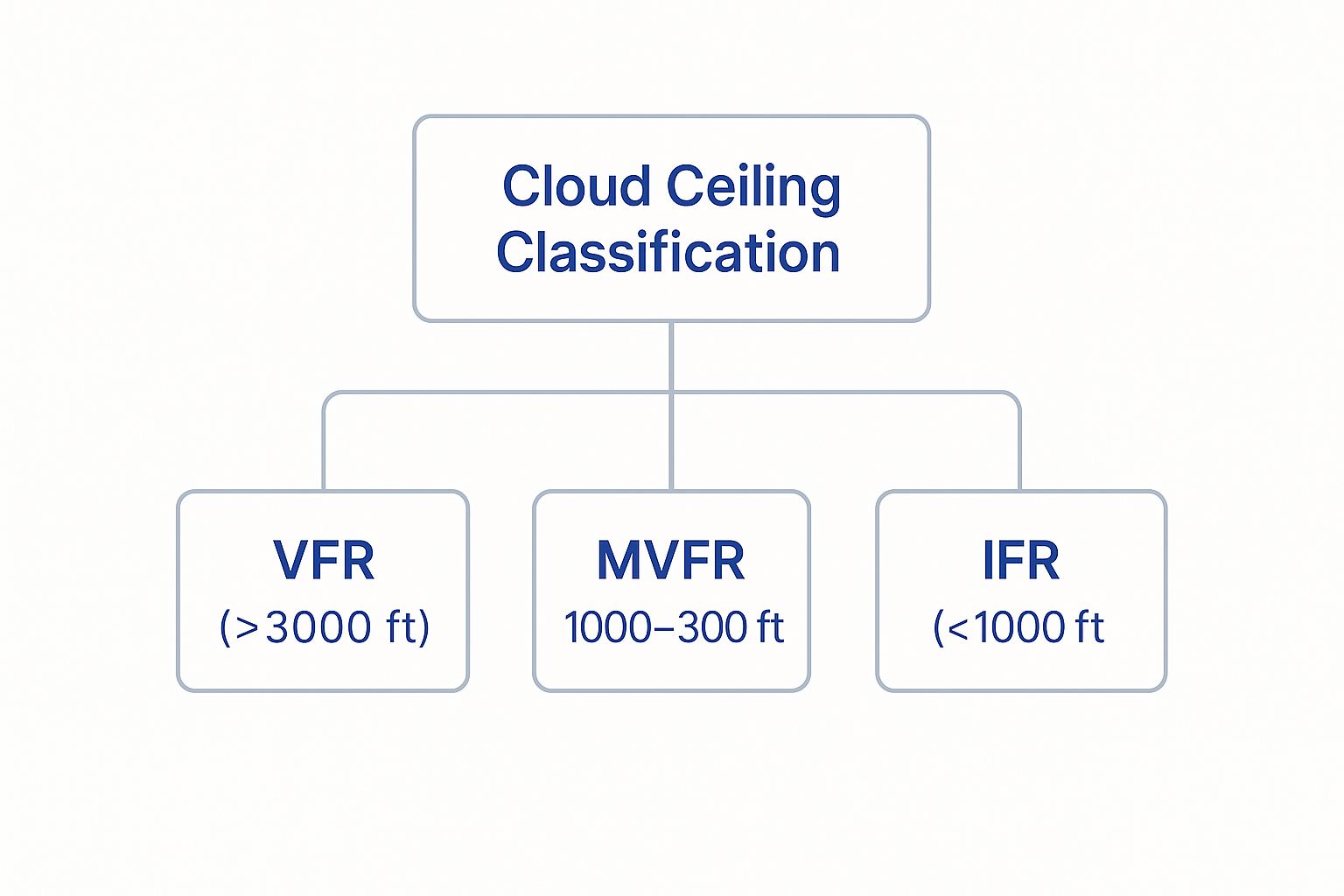

Visualizing Flight Rule Categories

To see how these thresholds stack up, the diagram below lays out the standard flight condition categories based on cloud ceiling height.

Conditions are broken down into VFR, MVFR, and IFR. A drop below a 1,000-foot ceiling significantly changes the operational landscape, imposing the most restrictive flight rules and grounding many operations.

The cloud ceiling is officially defined as the height above ground level (AGL) of the lowest cloud layer that covers more than half the sky. This single data point is a cornerstone of aviation safety and has a massive influence on pilot decisions, especially for flights that need clear visual contact with the ground.

Cloud Ceiling Thresholds and Flight Operations Status

This table provides a quick reference for how different ceiling heights typically affect flight operations.

| Ceiling Height (Feet AGL) | Flight Rule Category | Typical Impact on Operations | Relevance for Business |

|---|---|---|---|

| > 3,000 | VFR (Visual Flight Rules) | Operations are generally unrestricted. Ideal for visual tasks like aerial surveys and helicopter transport. | Minimal weather-related disruptions. High operational reliability. |

| 1,000 - 3,000 | MVFR (Marginal VFR) | Operations become more challenging. Some VFR flights may be canceled or delayed. Increased caution is required. | Potential for minor delays; requires proactive monitoring of weather conditions. |

| 500 - < 1,000 | IFR (Instrument Flight Rules) | VFR flights are prohibited. Only IFR-equipped aircraft with certified pilots can fly, often leading to significant delays. | High risk of disruption. Grounds most helicopter and small aircraft operations. |

| < 500 | LIFR (Low IFR) | The most restrictive conditions. Even many IFR flights are canceled or delayed. Airport operations may be halted. | Severe operational impact. Expect widespread cancellations and transportation shutdowns. |

Anticipating where the ceiling is likely to be is essential for mitigating disruptions before they occur. It allows business leaders to make proactive, data-informed decisions instead of reacting to unforeseen delays.

How Cloud Ceiling Data Is Measured and Reported

For Texas business leaders, making sound operational decisions means relying on precise, timely data. Cloud ceiling information is not a guess; it is the product of sophisticated, automated technology deployed at airports from El Paso to Beaumont. This reliable data stream is the backbone of safe aviation.

The primary tool for this measurement is a specialized laser-based instrument called a ceilometer. These devices emit a beam of light upwards and measure the time it takes for the light to reflect off the cloud base, calculating its height with high accuracy.

Automated Weather Observation Systems

At most airports, ceilometers are integrated into one of two main automated weather systems that provide a constant flow of meteorological data:

- ASOS (Automated Surface Observing System): This is the comprehensive system used at major airports, providing a full suite of weather data including cloud height, visibility, and wind speed.

- AWOS (Automated Weather Observing System): A similar system, often found at smaller regional and municipal airports, delivering essential weather updates needed for safe operations.

These systems are critical for providing the consistent, real-time measurements that pilots and logistics coordinators depend on. Today's automated systems can determine cloud height with an accuracy of ±50 feet. Over 90% of airports serving commercial passengers worldwide now use some form of automated ceiling measurement, feeding data into standard reports issued hourly. You can learn more about how pilots interpret this data on Boldmethod.com.

This raw data is then compiled into a standardized format used throughout the aviation industry.

Decoding the METAR Report

That standard report is called the METAR (Meteorological Aerodrome Report). While it may look like a cryptic line of code, it is a highly efficient method for communicating complex weather information. Learning to identify cloud ceiling data within a METAR is a valuable skill for any executive managing aviation-dependent operations.

Here’s an example of what a METAR looks like—it packs all key weather variables into a single line.

In this report, the cloud information is coded as "SCT038" (Scattered clouds at 3,800 feet) and "BKN049" (Broken clouds at 4,900 feet). The ceiling is always the lowest "Broken" (BKN) or "Overcast" (OVC) layer. Therefore, in this example, the cloud ceiling is 4,900 feet.

Knowing how to extract this specific number from a report empowers you to make informed risk assessments, a process you can enhance with the right climate risk assessment tools.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided in this article is for educational and informational purposes only and should not be interpreted as financial advice or an insurance recommendation.

Understanding the FAA Rules That Ground Flights

The reason one flight receives clearance while another remains on the tarmac almost always comes down to the specific Federal Aviation Administration (FAA) regulations governing that flight. These rules are not one-size-fits-all; they are designed to match the flight type to the weather, especially the cloud ceiling aviation environment.

It all starts with two fundamental sets of rules: Visual Flight Rules (VFR) and Instrument Flight Rules (IFR). VFR is the baseline for most private aviation and requires pilots to maintain a clear view of the ground and horizon. A standard VFR minimum is a cloud ceiling of 1,000 feet with at least three miles of visibility. If conditions drop below that, VFR flight is prohibited.

This is where IFR becomes essential. Pilots and aircraft certified for IFR can navigate using only their instruments, allowing them to fly safely through clouds. This capability is the single biggest factor for all-weather operational reliability.

How Flight Regulations Impact Your Operations

Regulations become more specific when looking at the type of flight operation, primarily split between FAA Part 91 and Part 135. For any business vetting an aviation partner, this distinction is critical.

- Part 91 Operations: These rules cover private, non-commercial flights, such as a corporate-owned jet. The pilot has more flexibility in making weather-related decisions.

- Part 135 Operations: This is the key regulation for businesses hiring aircraft. Part 135 governs commercial charter flights, from crew transport to critical cargo deliveries. The rules are much stricter, demanding higher weather minimums for both takeoff and landing to ensure passenger safety.

A Part 135 charter helicopter heading for a pipeline inspection might be grounded by a 900-foot ceiling, while a privately owned aircraft under Part 91 could legally take off. This is not about pilot skill; it's a mandatory safety standard built into the regulations.

This regulatory difference has direct consequences for Texas businesses. A chartered helicopter needed for an urgent inspection at a West Texas energy site will face tighter weather restrictions than a company-owned one. An emergency parts delivery to a Houston-area manufacturing plant on a charter service is subject to these same higher safety thresholds.

These strict requirements are a key factor in operational resilience, much like the planning detailed in our guide to hurricane preparedness for businesses. Knowing your aviation provider’s certification—and whether they can operate under IFR—is crucial for anticipating and mitigating weather disruptions that could otherwise derail your supply chain and operations.

Calculating the Real Cost of Low Ceilings

When a METAR report shows a low cloud ceiling, it is more than an inconvenience for pilots—it’s a direct threat to your bottom line. That weather data is the first signal of a potential business disruption. The real cost isn't one delayed flight; it's the start of a costly chain reaction that can ripple through your entire operation.

This is not a rare problem. FAA data shows that weather, particularly low ceilings and reduced visibility, is a primary factor in approximately 15-20% of all flight delays in the U.S. annually. It is consistently one of the top weather-related causes of operational disruptions. You can get a deeper dive into how pilots navigate these conditions over at PilotMall.com.

For industries here in Texas, these delays translate into specific and damaging financial impacts.

Quantifying Industry-Specific Financial Risks

A single grounded flight can initiate a cascade of financial and operational problems that differ for each sector. The initial delay is often just the beginning.

Consider these common scenarios for Texas businesses:

- Energy & Petrochemical: A chartered helicopter cannot fly a specialized repair crew to an offshore platform or a remote pipeline station. The result is extended production downtime, which can cost thousands of dollars per hour.

- Construction: A critical, custom-fabricated part for a major commercial project in Austin is stuck on the tarmac in Dallas. That one delay can bring work to a standstill for an entire team, triggering project overruns and penalty clauses.

- Agriculture: A shipment of time-sensitive produce from the Rio Grande Valley cannot be flown out. The delay risks spoilage and the complete loss of the product's value.

These examples show how a low cloud ceiling aviation event is not just a logistical hiccup but a direct financial liability.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided is for educational purposes only and should not be seen as financial advice or an insurance recommendation.

The Cascading Costs of Disruption

The total cost extends far beyond the immediate delay. To build a business case for mitigation, decision-makers must understand the secondary and tertiary impacts. These cascading effects often include idle labor costs, supply chain bottlenecks, damaged client relationships, and premium expedited shipping fees once conditions clear.

The table below breaks down these risks, connecting weather data directly to your balance sheet by outlining the specific operational threats and potential financial impacts of low cloud ceilings across key Texas industries.

Industry-Specific Impacts of Low Cloud Ceilings in Texas

| Industry Sector | Primary Aviation Use | Operational Risk from Low Ceilings | Potential Financial Impact |

|---|---|---|---|

| Energy & Petrochemical | Crew transport, site inspections, emergency parts delivery. | Delayed crew changes and critical repairs, halted inspections. | Production downtime, increased safety risks, project delays. |

| Manufacturing | Just-in-time parts delivery, executive travel. | Supply chain interruptions, halted production lines. | Lost production revenue, contractual penalties, expedited freight costs. |

| Logistics | High-value, time-sensitive cargo shipments. | Missed delivery windows, supply chain bottlenecks. | Damaged client trust, contractual fines, loss of perishable goods. |

| Agriculture | Aerial surveys, crop dusting, transport of perishable goods. | Inability to assess crop health, delayed planting/treatment, product spoilage. | Reduced crop yields, complete loss of high-value shipments. |

| Construction | Transport of specialized equipment/materials, site surveys. | Project standstills, idle crews and machinery. | Labor cost overruns, project timeline penalties, equipment rental fees. |

By quantifying these potential losses, executives can shift from a reactive to a proactive stance. This data-driven approach is fundamental to creating effective business risk management strategies that protect operations from inevitable weather disruptions.

Building Resilience to Aviation Weather Delays

Understanding the impact of a low cloud ceiling is one thing; building an operation that can withstand it is what protects your business. For Texas companies in fast-moving sectors like energy and logistics, this means developing contingency plans instead of reacting when a flight is canceled.

While weather is uncontrollable, your response is not. With the right plans in place, you can reduce downtime and maintain operational momentum even when conditions are unfavorable.

Fortifying Your Operational Playbook

True resilience begins with a clear, actionable plan. This is a pre-vetted strategy your team can execute the moment a forecast for a low cloud ceiling threatens your schedule, empowering them to pivot without delay.

Key strategies for your operational playbook include:

- Pre-Arranged Ground Transportation: Identify and establish relationships with reliable ground freight and passenger transport services in key operational areas. When an aviation asset is grounded, a pre-vetted alternative is a phone call away.

- Alternate Airport Analysis: Work with your aviation provider to map out viable alternate airports that may have better weather conditions. Delivering critical personnel or cargo to a nearby location is often a workable solution when the primary destination is unavailable.

Thinking through these alternatives ahead of time is the core of a solid operational continuity strategy. For a more detailed framework, our guide on how to create a disaster recovery plan can help structure this process.

Vetting Aviation Partners for All-Weather Capability

The most important factor in your resilience plan is the capability of your aviation partner. Not all providers are equipped to handle adverse weather, and it is crucial to understand this difference before signing a contract.

When selecting an aviation charter service, prioritize partners with a strong Instrument Flight Rules (IFR) program. IFR-certified pilots and aircraft can legally and safely fly in low-ceiling conditions that ground VFR-only operations. This capability dramatically expands your operational window, turning a potential shutdown into a manageable flight.

A provider with a robust IFR program and a modern fleet is more than a vendor; they are a strategic asset. Their ability to operate safely in marginal weather directly translates to greater reliability for your business, whether you're moving crews to the Permian Basin or parts to a Dallas factory.

Integrating Technology and Communication

Finally, leverage technology to stay ahead of weather disruptions. Waiting for your provider to call with a cancellation notice is too late.

- Advanced Weather Forecasting: Integrate real-time weather data and forecasting tools into your daily logistics planning. Modern services that provide predictive ceiling and visibility analytics can give you hours—or even days—of advance warning.

- Clear Communication Protocols: Establish a clear line of communication with your aviation provider. This should include predefined triggers for weather updates and a joint process for making go/no-go decisions when conditions are marginal.

By combining contingency planning, careful partner selection, and proactive monitoring, any Texas business can build a formidable defense against disruptions caused by low cloud ceilings.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided is for educational purposes only and should not be seen as financial advice or an insurance recommendation.

Common Questions About Cloud Ceilings

For those managing logistics and operations, understanding key aviation weather concepts is vital for effective planning. Here are straightforward answers to common questions from Texas business leaders about cloud ceilings.

What's the Difference Between a Cloud Ceiling and Cloud Cover?

Cloud cover is a general description, while a cloud ceiling is a precise measurement. Cloud cover simply describes how much of the sky contains clouds, using terms like "scattered" or "overcast."

A cloud ceiling, conversely, is the specific, measured height of the lowest cloud layer when the sky is more than halfway covered. For operational planning, the ceiling is the critical number. It is the hard limit for pilots flying visually (under VFR) and directly dictates whether many flights can take off.

How Can We Keep an Eye on Potential Flight Delays?

Proactive monitoring of weather conditions does not require a dedicated meteorologist. Publicly available tools like the FAA's Aviation Weather Center are invaluable, offering real-time METAR reports and Terminal Aerodrome Forecasts (TAFs) for any airport in the country.

TAFs are particularly useful for forward-looking planning, as they forecast conditions, including expected ceilings, for the next 24 to 30 hours. By checking the TAFs for your departure and arrival airports, you can identify potential disruptions a full day in advance. This data can also be integrated into logistics software to trigger automated alerts when conditions appear unfavorable.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided is for educational purposes only and should not be seen as financial advice or an insurance recommendation.

Why Can One Helicopter Fly in Low Ceilings When Another Is Grounded?

This difference almost always comes down to aircraft avionics and pilot training. A helicopter operating under basic Visual Flight Rules (VFR) is required by law to remain clear of clouds. If the ceiling is too low, that pilot is legally grounded.

However, an aircraft and pilot certified for Instrument Flight Rules (IFR) are equipped and trained to fly safely through clouds, relying solely on the aircraft’s instruments for navigation. IFR certification is the single most critical factor for maintaining operational uptime in poor weather.

When selecting an aviation partner for a critical mission—whether moving a crew or delivering a vital part—it is essential to inquire about their IFR capability. An IFR-certified operator can fly when VFR-only outfits are grounded, providing your business a significant advantage against weather-related delays.

At ClimateRiskNow, we provide Texas businesses with the detailed, site-specific weather risk intelligence needed to make smarter strategic decisions. Our assessments analyze your operational exposure to events like extreme heat, flooding, and freezes, helping you protect assets and maintain continuity. We transform complex climate data into a powerful risk management tool.

Learn more and request your customized assessment at https://www.climaterisknow.com.