Think of transformer oil analysis as a diagnostic check-up for your most critical electrical assets. For business decision-makers in Texas industries like Energy, Manufacturing, and Agriculture, it is a vital practice for assessing operational risk. This guide explains how sampling and testing insulating oil provides a clear picture of a transformer's internal health, offering an early warning of stress, contamination, or developing faults long before they cause a catastrophic failure.

Why Transformer Oil Analysis is a Critical Risk Management Tool

For Texas's core industries—from Energy and Petrochemical to Manufacturing and Agriculture—a transformer isn't just another piece of equipment. It's the heart of the entire operation. A failure can trigger immediate and expensive unplanned downtime, bringing production and supply chains to a halt. This is where transformer oil analysis becomes a strategic component of managing operational risk, particularly in the face of extreme weather events that strain electrical infrastructure.

The oil circulating inside a transformer is an information goldmine. It cools the system, provides electrical insulation, and—most importantly—it collects microscopic evidence about internal conditions. Over time, high operational loads and the relentless Texas heat can accelerate the breakdown of both the oil and the transformer's solid insulation.

The Strategic Value of Proactive Health Monitoring

By regularly analyzing this oil, you can uncover a detailed story about the asset's condition and spot subtle signs of trouble before they escalate. This proactive approach is fundamental to maintaining operational continuity and protecting high-value equipment. Data from a simple oil sample can prevent a multi-million dollar asset loss and associated business interruption.

The growing need for a stable electrical supply is driving major investment in asset reliability. The global transformer oil market was valued at around USD 3.32 billion in 2025 and is projected to hit USD 9.53 billion by 2034, a clear sign of increasing global electricity demand. You can explore the full transformer oil market report to understand the drivers behind this growth.

By interpreting the data from an oil analysis, you are essentially monitoring your transformer's health. This allows you to shift from reactive repairs to a proactive, data-driven asset management strategy, which is fundamental to building operational resilience against disruptions.

What the Analysis Looks For

This diagnostic process searches for specific chemical and physical markers that point to potential problems. These key metrics paint a clear picture of the transformer's health, helping executives make informed, data-driven decisions.

A typical analysis will screen for several key contaminants and byproducts:

- Moisture Content: Water is a primary enemy of transformer insulation. It accelerates aging and weakens the oil's ability to insulate, known as its dielectric strength.

- Acidity Levels: As oil degrades, it creates acidic compounds. If left unchecked, this acid can corrode the transformer's internal components, leading to premature failure.

- Dissolved Gases: Different types of electrical or thermal faults generate specific gases. These gases act like fingerprints, indicating problems like overheating or internal arcing.

Monitoring these and other key indicators provides the foresight needed to schedule maintenance on your terms—not during a costly emergency.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided in this article is for educational purposes only and should not be interpreted as financial advice or an insurance recommendation.

Decoding the Data: What Your Transformer Oil Reveals

An oil analysis report can appear dense with technical data. However, understanding it is key to translating technical readouts into a clear assessment of your transformer's health and the associated operational risks.

We can break this down by starting with simple visual checks and then moving into more complex chemistry. Each test reveals another piece of the puzzle, providing a complete view of what's happening inside the transformer and flagging potential threats before they lead to failure.

Physical and Chemical Warning Signs

Often, the first clues are the most basic. These physical and chemical properties of the oil are the foundational vital signs in any serious transformer oil analysis.

- Color and Appearance: Healthy transformer oil should be pale yellow and clear. Darkening indicates oxidation and sludge buildup. A cloudy appearance almost always signifies the presence of water—a major red flag for Texas businesses, where high humidity can accelerate moisture ingress.

- Dielectric Strength: This is a direct measure of the oil’s ability to prevent an internal electrical arc. Contaminants, especially water, destroy this property and dramatically increase the risk of a catastrophic failure.

- Acidity (Neutralization Number): As oil degrades, it creates acidic compounds. High acidity corrodes paper insulation and metal parts, weakening the entire system from the inside out.

- Moisture Content: Water is one of the most destructive contaminants. It degrades paper insulation and reduces the oil's dielectric properties, causing the transformer to age faster and become dangerously vulnerable, especially during the high electrical demand of a summer heatwave.

Think of these indicators as a preliminary check-up. A change in color is an initial visual warning, while high acidity signals a chronic, underlying problem requiring attention.

A single transformer failure can halt production, disrupt supply chains, and incur repair costs that far exceed the price of routine maintenance. Identifying these early warning signs is the first step to preventing such a disaster.

Understanding Dissolved Gas Analysis (DGA)

The most powerful diagnostic tool is Dissolved Gas Analysis (DGA). As a transformer operates, heat and electrical stress break down the oil and insulation, releasing different gases. These gases dissolve into the oil, and their specific types and amounts create a "fingerprint" that tells us exactly what kind of fault is developing.

Consider these gases as specific distress signals from your equipment:

- Hydrogen and Methane: These usually point to low-energy electrical activity, like corona discharge. It’s a slow-burn problem that degrades insulation over time.

- Ethane and Ethylene: Seeing these gases suggests a thermal fault—the transformer is overheating. Ethylene, in particular, signals a high-temperature "fever" that is likely damaging the winding insulation. This is a critical concern for assets operating under heavy loads during Texas summers.

- Acetylene: This is the most urgent alarm. Acetylene is only created by the extremely high temperatures of an electrical arc. It indicates a dangerous fault is happening and requires immediate action.

Analyzing gas ratios allows a skilled technician to pinpoint the problem with high accuracy. This empowers maintenance teams to move from knowing something is wrong to understanding exactly what’s happening. For Texas businesses, DGA provides the foresight needed to prevent a catastrophic failure, which is essential for maintaining operations and building a more robust supply chain with Climaterisknow.com.

Key Transformer Oil Analysis Tests and Their Operational Implications

| Test Type | What It Measures | What High/Abnormal Levels Indicate | Potential Business Impact |

|---|---|---|---|

| Dielectric Strength | Oil's ability to insulate against electrical voltage. | Contamination (water, particles), increasing risk of internal arcing. | Increased risk of sudden, catastrophic failure and unplanned downtime. |

| Acidity | Presence of acidic byproducts from oil oxidation. | Accelerated aging of paper insulation and internal corrosion. | Reduced transformer lifespan; potential for costly premature replacement. |

| Moisture Content | Amount of dissolved water in the oil (measured in ppm). | Severe degradation of paper insulation and reduced dielectric strength. | Higher probability of failure during electrical surges or faults. |

| Dissolved Gas Analysis (DGA) | Specific gases produced by thermal or electrical faults. | Overheating (ethylene), arcing (acetylene), or partial discharge (hydrogen). | Early warning of specific internal faults, allowing for planned maintenance instead of unexpected outages. |

| Color & Appearance | Visual signs of oil degradation and contamination. | Oxidation, sludge formation, or the presence of free water. | An initial, simple indicator that more in-depth testing is urgently needed. |

These tests work together to build a comprehensive health profile. An abnormal color might trigger a more detailed moisture and acidity test, while a concerning DGA result can help you schedule a specific repair before the equipment fails entirely.

Translating Test Data Into Strategic Decisions

A lab report is only valuable when its data is translated into actionable insights. The real power of transformer oil analysis is turning raw data into a clear story about your equipment's health to inform cost-effective decisions that maintain operational continuity.

For any Texas-based industry, where equipment constantly battles heat and heavy demand, this is a critical business function. It moves you from reactive, expensive repairs to a proactive, strategic advantage. Trends over time tell you far more than a single snapshot ever could. For example, a slow, steady rise in acidity may indicate normal aging, manageable with planned maintenance. A sudden spike in combustible gases, however, demands immediate action to prevent a failure.

The Power of Trend Analysis

Your first oil analysis report establishes a baseline. While useful, the real diagnostic value comes from comparing reports over time. This trend analysis is the heart of predictive maintenance.

Imagine a manufacturing plant in North Texas where one transformer powers the entire production line. A single test showing slightly elevated moisture might not seem urgent. But if you plot that data against the last three years of reports and see a clear, consistent upward trend, you now have an actionable insight.

This trend points to a slow but persistent leak or perhaps a failing breather system. Armed with that knowledge, you can schedule a targeted repair during a planned shutdown, avoiding a surprise failure during peak production. This proactive approach is a cornerstone of effective operational risk management.

Establishing Benchmarks with Industry Standards

To determine if a reading is a minor issue or a major red flag, we turn to industry standards. These provide the context needed to evaluate results objectively. The two most important standard-setting bodies are the Institute of Electrical and Electronics Engineers (IEEE) and ASTM International.

These organizations publish detailed guides that define acceptable limits for transformer oil properties.

- IEEE Standards (e.g., C57.104): This is the primary guide for interpreting dissolved gas analysis (DGA) data. It provides tools, like the Duval Triangle, that help diagnose the specific type of fault—such as overheating or arcing—based on gas concentrations.

- ASTM Standards (e.g., D3487): This standard specifies the quality requirements for new mineral insulating oil, defining benchmarks for properties like dielectric strength, acidity, and moisture content.

These standards are essential tools for business leaders. They offer an objective way to evaluate test results and facilitate informed discussions with maintenance teams, helping to verify whether a recommendation for a costly repair is justified by the data.

By comparing your transformer’s test results to established IEEE and ASTM limits, you transform raw data into a clear risk assessment. This is the moment a technical report becomes a strategic document, guiding decisions on maintenance spending and capital planning.

Data from your transformer oil analysis, placed in the context of industry standards and historical trends, directly informs critical business decisions. It provides the clarity to decide whether to schedule simple oil filtration, adjust operational loads, or begin budgeting for a replacement. For any Texas business focused on operational resilience, that foresight is indispensable.

Building a Proactive Maintenance Program

Moving from data interpretation to action is where a transformer oil analysis program delivers its return on investment. This is how a diagnostic tool becomes a strategic asset, shifting your entire approach from expensive, reactive repairs to smart, planned upkeep. This framework must be tailored to your specific operational realities.

For businesses in Texas, that means factoring in unique environmental stressors. A transformer in the humid, salt-laced air of the Gulf Coast faces a higher risk of moisture ingress than one in the dry conditions of West Texas. Likewise, a transformer at a high-demand manufacturing plant near Dallas requires more frequent monitoring than a backup unit at a rural co-op.

An effective program starts with a smart testing schedule based on the risk profile of each asset.

Setting the Right Testing Cadence

The frequency of your transformer oil testing should be a calculated decision. It’s about allocating resources where they’re needed most, avoiding the mistakes of under-testing critical assets and over-testing less important ones.

When mapping out your schedule, weigh three key variables:

- Asset Criticality: How vital is this transformer to your operation? The main transformer at a petrochemical plant may warrant annual or even semi-annual testing. A smaller, redundant unit might only need testing every two to three years.

- Age and Condition: An older transformer with a history of issues warrants more frequent check-ups. For a new unit, test it within the first year to establish a baseline, then adjust the frequency based on observed trends.

- Operating Environment: Transformers exposed to extreme heat, heavy load cycles, or corrosive environments are under more stress. These assets need a more aggressive testing schedule to catch accelerated aging and contamination.

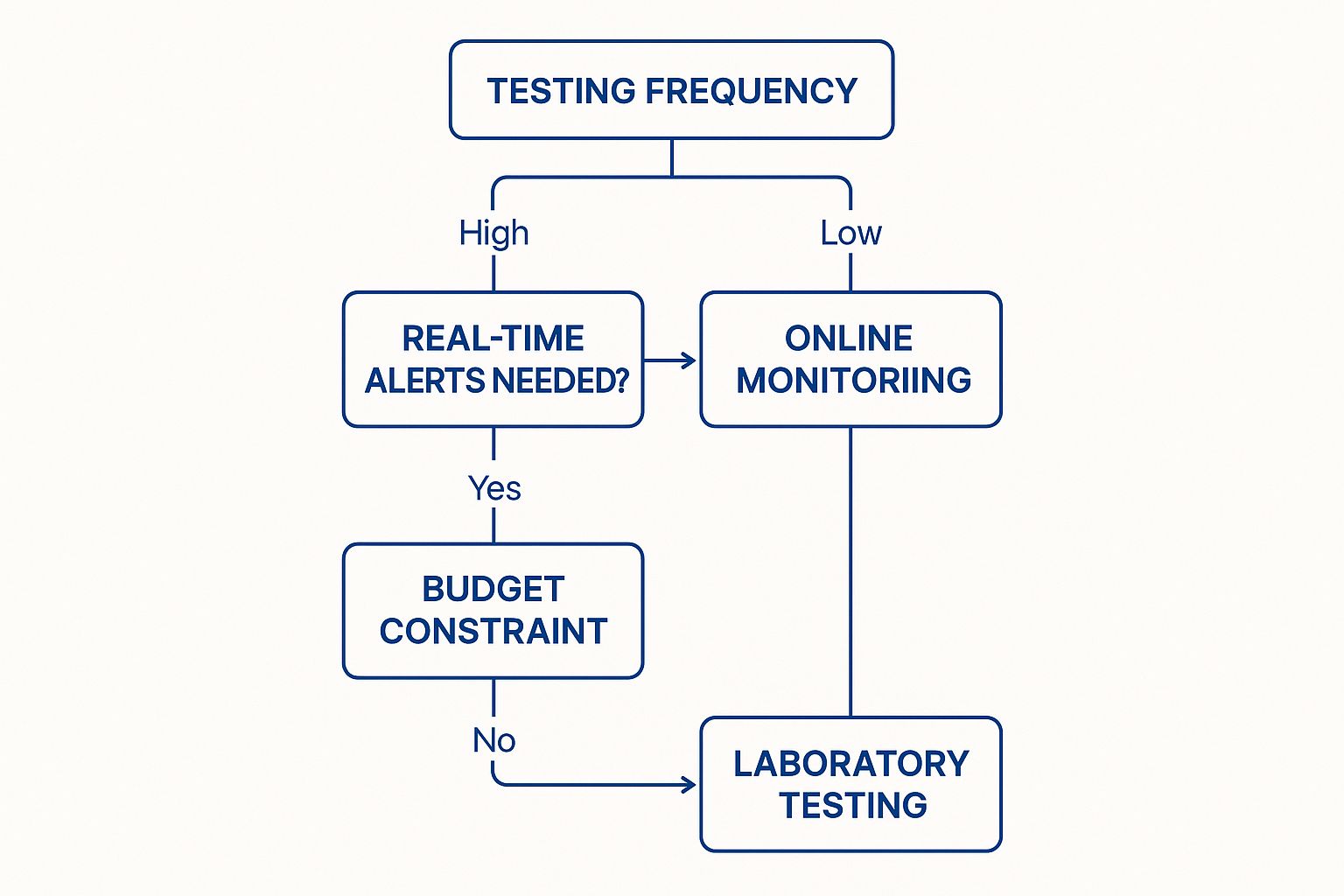

This infographic lays out a simple decision tree to help you decide between traditional lab testing and continuous online monitoring, depending on operational demands.

As the visual makes clear, for highest-priority assets requiring constant oversight, online monitoring is the optimal solution. For most other scenarios, scheduled lab testing provides the necessary data cost-effectively.

Choosing a Lab and Creating an Action Plan

Once you have a schedule, selecting a qualified testing lab is the next critical step. Look for a lab with proven experience in transformer diagnostics and appropriate industry accreditation. Request sample reports and ask how they flag urgent results.

The final piece is a clear, pre-defined action plan. This removes guesswork and ensures a consistent, logical response to analysis findings.

A proactive maintenance plan is a living document. It translates oil analysis data into a clear set of instructions—'If we see X, we do Y'—transforming maintenance from a cost center into a strategic investment in operational reliability.

Your action plan should specify steps for different findings:

- Normal/Acceptable Results: Continue routine monitoring according to the established schedule.

- Minor Issues (e.g., slightly elevated moisture): Schedule on-site oil filtration or dehydration during the next planned outage. This is a low-cost fix that prevents a small problem from escalating.

- Significant Issues (e.g., rising acidity, moderate gassing): Plan for more intensive workshop repairs, like oil reclamation. Taking these proactive steps is crucial for managing potential risks related to equipment breakdown and extending asset life.

- Critical Alarms (e.g., high levels of acetylene): This requires immediate attention. The unit should be de-energized as soon as it is safe to do so, and plans for internal inspection or emergency replacement should begin.

This structured approach ensures every transformer oil analysis report triggers a deliberate, value-driven action that protects both your assets and your bottom line.

Debunking Common Myths About Transformer Oil

Common misconceptions about transformer oil can lead to expensive and preventable failures. For Texas businesses in sectors like manufacturing and petrochemical, where uptime is critical, these misconceptions pose a direct threat to the bottom line.

One of the most dangerous beliefs is that "if it's running, it's fine." This overlooks how transformers typically fail. Major problems like insulation decay or slow overheating develop silently over months or years. By the time a visible symptom appears, it is often too late. A transformer can appear to operate perfectly while a critical fault develops internally, creating a false sense of security, especially during a Texas heatwave or a period of high demand. Regular transformer oil analysis is the only way to detect these hidden issues while they are still manageable.

The Cost of Inaction

Another myth is that oil analysis is an unnecessary expense. Some decision-makers view it as a maintenance cost that can be cut. This perspective ignores the massive financial impact of an unplanned outage.

The cost of a proactive oil analysis program is a small fraction of the expenses associated with an emergency transformer replacement, lost production, and supply chain disruptions. It is not a cost; it's an investment in operational continuity.

Consider a Texas-based agricultural processing facility. A few oil tests per year might cost a few thousand dollars. A single transformer failure during peak harvest season could trigger:

- Emergency Repair Costs: Sourcing and installing a new transformer on an emergency basis can cost 50% to 100% more than a planned replacement.

- Lost Production: Days or weeks of downtime can result in hundreds of thousands of dollars in lost revenue and spoiled inventory.

- Reputational Damage: Failure to meet contractual obligations can damage relationships with customers and partners.

Viewed this way, routine analysis is one of the most cost-effective risk management tools available. Maintaining asset health is fundamental to building resilience, a strategy that can be strengthened by using advanced climate risk assessment tools to understand broader environmental threats.

Not All Oils Are Created Equal

Finally, the myth that "all transformer oils are the same" is a dangerous oversimplification. The type of oil is a specific engineering choice, selected to match the unit's workload and environment. Using the wrong fluid can impair a transformer’s cooling and insulating capabilities. For example, while standard mineral oil is common, bio-based ester fluids have a much higher fire point, making them a safer choice for indoor or high-risk locations. Adhering to local Texas environmental and safety regulations is not optional, and selecting the correct oil is a critical part of compliance.

Protecting Your Assets With Data-Driven Analysis

As we've seen, transformer oil analysis is far more than a routine check-up. It is a strategic tool that provides direct insight into the health of your most valuable equipment. By learning to interpret the "language" of the oil, you can identify internal issues long before they become a crisis.

This visibility is mission-critical for maintaining uptime, especially in demanding Texas industries. Understanding the data enables smarter, more confident decisions about asset management that directly protect your bottom line. The key takeaway is simple: regular, proactive testing costs a fraction of a catastrophic failure.

A Strategic Investment in Resilience

Oil analysis should be viewed as a core investment in your company’s operational resilience. It is a foundational piece of any strong asset management program and directly supports broader business continuity goals.

Making informed decisions based on this data helps ensure your operations can withstand unexpected equipment stress and environmental pressures. It's a key part of understanding business continuity planning and distinguishes resilient companies from those vulnerable to sudden, costly disruptions. Ultimately, integrating a smart analysis program is about securing long-term success by keeping essential assets online and productive.

By shifting from a reactive repair mindset to a proactive, data-driven strategy, you transform a technical task into a powerful driver of business stability and long-term financial health. This approach is the cornerstone of modern operational risk management.

As a final reminder, ClimateRiskNow does not sell insurance or financial products. The information provided throughout this article is for educational purposes only and should not be interpreted as financial advice or an insurance recommendation. Your operational decisions should be made in consultation with qualified engineering and financial professionals.

Answering Key Questions from Business Leaders

Here are answers to common questions from executives about transformer oil analysis, designed to help you make smarter decisions to protect your critical assets.

How Often Should We Test Our Transformer Oil?

There is no single answer. The right testing frequency depends on the transformer's risk profile—its age, voltage, and criticality to your operations.

For a high-voltage, mission-critical unit, such as one powering a continuous manufacturing line, annual testing is the standard. For smaller, less critical transformers, testing every two to three years may be sufficient.

A non-negotiable rule: any new transformer should be tested within its first year. This first analysis provides a vital baseline against which all future tests will be measured, making it easier to spot deviations.

What Is the Single Most Important Test?

If you could only choose one, it would be Dissolved Gas Analysis (DGA). While a full suite of tests provides a complete picture, DGA is the most powerful single diagnostic tool for detecting active internal faults early.

Think of DGA as an early warning system for major problems—arcing, partial discharge, and severe overheating. It often flags these issues long before they escalate into a catastrophic failure. In short, it provides the earliest and most specific alert that a serious fault is developing inside your transformer.

Dissolved Gas Analysis translates the microscopic byproducts of electrical and thermal stress into a clear diagnosis. It lets you understand not just that a problem exists, but precisely what kind of problem it is, paving the way for a targeted and effective maintenance response.

Can Transformer Oil Be Reused After Treatment?

Yes, in many cases. Transformer oil can often be successfully treated and returned to service. This process, known as oil reclamation or reconditioning, is typically more cost-effective than a full replacement.

If the oil is contaminated with moisture or particles, specialized equipment can filter and dehydrate it, restoring its dielectric properties. This is a common maintenance procedure for large transformers.

However, treatment isn't always a solution. If the oil is chemically degraded—for example, if it has a very high acid level indicating advanced oxidation—a complete oil replacement is likely the only way to ensure the transformer's long-term health and reliability.

ClimateRiskNow provides location-specific risk assessments that empower Texas businesses to protect their most critical assets from extreme weather events. Our detailed reports help you understand your operational vulnerabilities and build a more resilient future. Request a demo to see how we can help you turn complex climate data into a strategic advantage.