For Texas business leaders in energy, manufacturing, logistics, agriculture, and construction, the operational landscape is increasingly defined by extreme weather. From the freezing grip of a winter storm like Uri, which caused an estimated $130 billion in economic damages, to the devastating force of a hurricane like Harvey, supply chain disruptions are no longer a possibility, but an inevitability. A reactive stance is a direct threat to your bottom line, operational continuity, and market reputation. Proactive planning is paramount.

This article outlines nine actionable, data-driven supply chain risk management strategies designed to help Texas enterprises assess vulnerabilities, prepare for disruptions, and build a more resilient operational framework. We will move beyond theory to provide practical implementation details and localized insights tailored to the unique challenges of the Texas climate. You will learn how to implement supplier diversification, enhance visibility with localized intelligence, and create robust business continuity plans that account for specific weather threats. By adopting these strategies, your organization can fortify its operations, protect its assets, and maintain a competitive edge when disruptions occur.

1. Strategic Supplier Diversification: Building a Resilient Sourcing Network

Over-reliance on a single supplier, especially one located in a high-risk weather zone like the Texas Gulf Coast, creates a critical point of failure in any supply chain. One of the most effective supply chain risk management strategies is strategic supplier diversification. This approach involves intentionally sourcing materials and components from multiple, geographically distinct partners to build operational redundancy.

When a primary supplier is impacted by a localized event, such as a hurricane causing widespread power outages or a severe thunderstorm leading to flash floods, having alternate sources prevents a complete production shutdown. For Texas manufacturers, this could mean sourcing critical components from partners in both Central Texas and another state, mitigating the risk of a single regional disaster halting operations.

How to Implement Strategic Diversification

A successful diversification strategy goes beyond simply having a backup. It requires a proactive, structured approach. A Houston-based petrochemical company, for example, might dual-source critical catalysts from suppliers in both Louisiana and Oklahoma. This protects against hurricane-related disruptions along the Gulf Coast, ensuring production continuity. Similarly, a Dallas construction firm could contract with aggregate suppliers from both North Texas and a neighboring state to avoid project delays from localized flooding events.

To implement this effectively, consider these actionable steps:

- Maintain at least two to three qualified suppliers for every critical component.

- Establish clear criteria for supplier selection, including their own risk management plans.

- Create supplier scorecards to track performance, quality, and reliability over time.

- Regularly audit suppliers for financial health and operational stability.

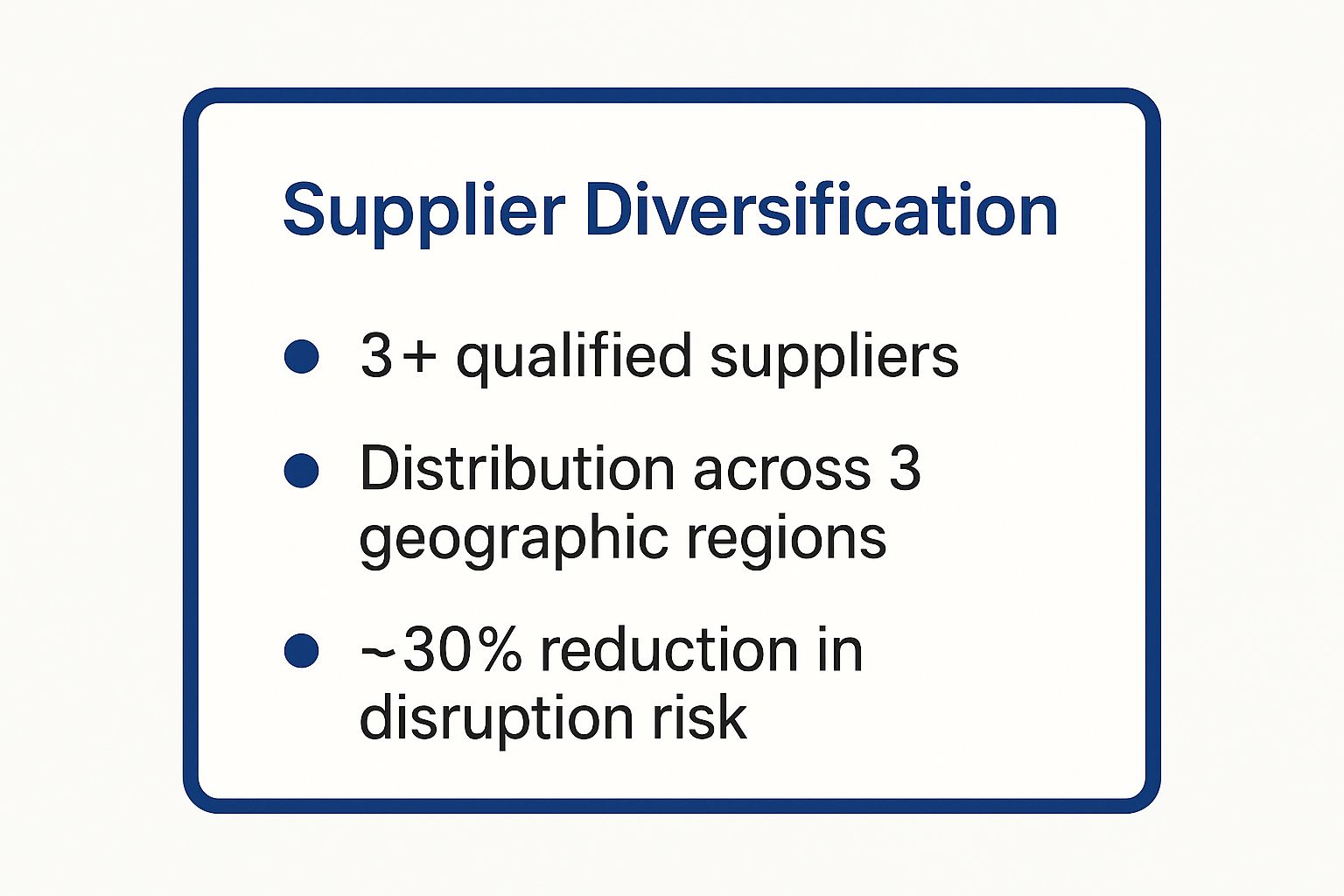

The following infographic highlights the core targets for a resilient, diversified sourcing network.

As the data shows, a well-executed strategy aiming for geographic and numerical diversity can significantly reduce the probability of severe disruptions. By spreading risk across different partners and regions, businesses can build a supply chain that is inherently more resilient to localized climate and weather events. You can explore a deeper analysis of supply chain risk mitigation on climaterisknow.com for more advanced techniques.

2. Supply Chain Visibility and Monitoring: Gaining Real-Time Insight

A lack of real-time information creates blind spots where disruptions can quickly escalate. One of the most critical supply chain risk management strategies is establishing end-to-end visibility and monitoring. This involves using technology to gain a comprehensive, real-time view of operations, from raw material sourcing to final delivery, allowing for proactive responses to potential threats.

When a severe weather front is forecast for a key transport corridor in Texas, such as I-10 along the Gulf Coast, real-time visibility allows a company to reroute shipments, alert downstream partners of potential delays, and activate contingency plans. Without this insight, cargo could be stranded, leading to production halts and missed delivery deadlines. Advanced monitoring provides the intelligence needed to pivot before a disruption fully materializes.

How to Implement Visibility and Monitoring

Effective implementation integrates technology and process to create a unified operational picture. A manufacturing firm in Fort Worth, for instance, could use GPS tracking and IoT sensors on critical shipments traveling from the Port of Houston. This allows them to monitor for delays caused by coastal storm surges and ensure temperature-sensitive materials remain within safe limits, preventing spoilage and financial loss.

To build a robust monitoring system, consider these actionable steps:

- Start with critical products and high-risk transportation routes.

- Invest in user-friendly dashboards to provide relevant insights to different stakeholders.

- Establish clear data-sharing agreements and standards with all supply chain partners.

- Regularly validate data accuracy to ensure the reliability of your monitoring system.

The following video from SAP provides further insight into how digital technologies are transforming supply chain management.

By leveraging technologies like IoT, GPS, and advanced analytics, businesses can move from a reactive to a proactive risk management stance. This capability is essential for building resilience against unpredictable events. You can discover more about building supply chain resilience against extreme weather on climaterisknow.com for a deeper understanding.

3. Demand Forecasting and Planning: Aligning Supply with Reality

Inaccurate demand signals can create massive inefficiencies, leading to either costly overstocking or damaging stockouts. Effective demand forecasting and planning is one of the most powerful supply chain risk management strategies because it aligns your entire operation with market realities. This process uses historical data, predictive analytics, and market intelligence to anticipate customer needs, allowing for optimized production schedules and inventory levels.

When a severe weather event is predicted for the Texas Gulf Coast, for example, a logistics company can use forecasting to anticipate a surge in demand for essential goods in inland cities like Austin and San Antonio. This foresight allows them to pre-position inventory and allocate transportation resources, ensuring they can meet customer needs without disruption. This proactive stance transforms a potential crisis into a managed operational adjustment.

How to Implement Demand Forecasting and Planning

A robust forecasting strategy is not about gazing into a crystal ball; it's a data-driven discipline. For instance, a major manufacturer might implement collaborative forecasting with key Texas retailers such as H-E-B. By sharing data and insights, they can more accurately predict demand for products like bottled water and batteries ahead of hurricane season, ensuring shelves remain stocked. This collaborative planning, forecasting, and replenishment (CPFR) is a best practice for mitigating weather-driven demand spikes.

To implement this effectively, consider these actionable steps:

- Combine multiple forecasting methods, such as statistical models and machine learning, for a more accurate consensus forecast.

- Involve sales and marketing teams in the process to incorporate their on-the-ground market intelligence.

- Regularly review and update forecasting models to ensure they remain accurate as market conditions change.

- Focus on forecast accuracy at the most relevant level, whether it's by product, region, or customer segment.

By anticipating demand with greater precision, businesses can reduce the bullwhip effect across their supply chains. This leads to lower safety stock requirements, reduced carrying costs, and a far more agile response to both predictable seasonal shifts and unexpected disruptions.

4. Strategic Safety Stock Management: A Buffer Against Uncertainty

Relying solely on just-in-time inventory can expose a supply chain to significant vulnerabilities, especially when faced with unpredictable disruptions like severe weather events. Strategic safety stock management is one of the most vital supply chain risk management strategies, involving the maintenance of optimal buffer inventory to shield operations from demand surges and supply interruptions. This method moves beyond simple stockpiling, using data to balance the cost of holding inventory against the risk of costly stockouts.

When a winter storm in North Texas disrupts transportation networks or a hurricane threatens Gulf Coast suppliers, having a calculated safety stock prevents a complete halt in production. For Texas businesses, this means being able to fulfill customer orders and maintain operations while competitors scramble for parts, providing a significant competitive advantage during regional crises.

How to Implement Strategic Safety Stock Management

An effective safety stock strategy is dynamic and data-driven, not a static "set and forget" number. For example, a Houston-based medical device manufacturer might hold extra inventory for life-saving devices, recognizing the high cost of a stockout. An agricultural equipment supplier in Lubbock would maintain a strategic buffer of critical parts before planting season, ensuring farmers can operate without delay during their most crucial operational window.

To implement this sophisticated approach, consider these actionable steps:

- Use ABC analysis to classify inventory and focus safety stock investments on high-value, critical items ("A" items).

- Calculate safety stock levels based on desired service level targets, demand variability, and supplier lead time fluctuations.

- Consider supplier reliability metrics when determining buffer levels; less reliable suppliers require larger safety stocks.

- Regularly review and adjust parameters as market conditions, demand patterns, and supplier performance change.

- Implement multi-echelon inventory optimization (MEIO) to position stock strategically across the entire network, from central warehouses to regional distribution centers.

By methodically calculating and placing buffer inventory, companies can absorb shocks from weather events and other disruptions, ensuring business continuity and customer satisfaction. This proactive inventory management is a cornerstone of a truly resilient supply chain.

5. Business Continuity and Disaster Recovery Planning

A reactive approach to supply chain disruptions can lead to significant financial loss and reputational damage. An essential component of any robust supply chain risk management strategy is developing a comprehensive Business Continuity and Disaster Recovery (BC/DR) Plan. This proactive strategy prepares an organization to maintain critical functions during and after a disruption, ensuring a swift and organized recovery.

BC/DR planning involves creating detailed response protocols, establishing alternative operational processes, and setting up backup systems for everything from data to physical production lines. For Texas-based industries, this means planning for scenarios like a hurricane disrupting a Gulf Coast petrochemical facility or a winter storm taking down the power grid for a manufacturing plant in Dallas. A well-designed plan minimizes downtime and protects an organization's bottom line.

How to Implement BC/DR Planning

Effective BC/DR planning is a continuous cycle of assessment, development, and testing, not a one-time task. For instance, a logistics company in Houston can develop contingency plans that reroute shipments through alternative hubs in San Antonio or Dallas if port operations are suspended due to a tropical storm. An agriculture business might have plans for sourcing feed from alternate regions in the event of a localized drought impacting their primary suppliers.

To implement this strategy effectively, consider these actionable steps:

- Conduct a Business Impact Analysis (BIA) to identify critical processes and the potential impacts of disruption.

- Establish clear Recovery Time Objectives (RTO) and Recovery Point Objectives (RPO) for each critical function.

- Create cross-functional crisis management teams with defined roles and responsibilities.

- Test the plan regularly through tabletop exercises, simulations, and full-scale drills.

By formalizing these protocols, Texas businesses can build the institutional resilience needed to withstand severe weather events and other unforeseen disruptions. This structured approach moves an organization from a position of vulnerability to one of preparedness. You can find out more about a deeper dive into what business continuity planning is on climaterisknow.com for more detailed guidance.

6. Supplier Relationship Management (SRM)

In a volatile environment, transactional supplier relationships are a liability. A more advanced supply chain risk management strategy is Supplier Relationship Management (SRM), which shifts the focus from cost-based transactions to collaborative, value-driven partnerships. This approach involves deeply integrating with key suppliers to align on goals, share risk, and drive mutual improvement, creating a more transparent and resilient supply chain.

When a weather event like an unexpected freeze disrupts a supplier's operations in West Texas, a strong SRM framework means you receive proactive communication, not radio silence. This collaborative relationship facilitates joint problem-solving, such as rerouting shipments or co-investing in preventative measures. It transforms suppliers from mere vendors into strategic partners who are invested in your operational continuity.

How to Implement Supplier Relationship Management

Effective SRM requires segmenting suppliers and investing resources where they matter most. For instance, a Houston-based chemical manufacturer might establish a joint planning committee with its most critical raw material provider. This committee would meet regularly to review weather forecasts, co-develop contingency plans for hurricane season, and align on inventory strategies to buffer against potential disruptions.

To implement this effectively, consider these actionable steps:

- Segment suppliers based on their strategic importance and risk profile.

- Establish joint performance metrics that include risk and resilience indicators.

- Create clear governance structures, such as executive check-ins and operational reviews.

- Invest in shared technology for better visibility into forecasts, inventory, and logistics.

- Develop joint business continuity plans specifically for high-impact weather scenarios.

Building these deep partnerships ensures that when a crisis hits, you have a network of allies ready to respond. This collaborative approach is a core principle discussed by leading emergency management companies on climaterisknow.com that specialize in private sector resilience. By investing in relationships, you build a supply chain that is not just robust but also agile and responsive to unforeseen challenges.

7. Geographic Diversification and Nearshoring: Reducing Global Vulnerabilities

Relying heavily on a single geographic region for production or sourcing exposes a business to concentrated geopolitical, economic, and weather-related risks. A key element of modern supply chain risk management strategies is geographic diversification, a method that strategically spreads operations across different countries and regions. This includes the growing trend of nearshoring, which brings production closer to home markets to shorten lead times and reduce transit complexities.

When a major weather event, like a typhoon in Southeast Asia, or a geopolitical disruption halts operations in a key manufacturing hub, geographically diversified companies can shift production or sourcing to facilities in other regions. For a Texas-based electronics manufacturer, this means not relying solely on a factory in China, but also having production capabilities in Mexico or even within the U.S. to ensure a continuous flow of goods.

How to Implement Geographic Diversification and Nearshoring

Effective geographic diversification requires a holistic evaluation of risk and opportunity, not just a simple cost comparison. A Texas construction firm might source certain fabricated steel components from Mexico instead of Asia to reduce shipping times and mitigate risks from port congestion. Similarly, energy companies have diversified LNG export terminals along the Gulf Coast to ensure that a single hurricane does not shut down their entire export capacity.

To implement this strategy effectively, consider these actionable steps:

- Analyze total cost of ownership, including logistics, tariffs, and inventory, not just labor costs.

- Evaluate regional infrastructure quality, political stability, and local supplier ecosystems.

- Assess proximity to key markets to determine if reduced lead times create a competitive advantage.

- Ensure access to skilled labor and plan for necessary training and development programs.

This approach transforms the supply chain from a linear, vulnerable chain into a dynamic and resilient network. By strategically positioning assets closer to home and across multiple regions, businesses can better navigate global uncertainties and protect their operations from distant crises.

8. Financial Risk Mitigation Tools

Financial instability within your supply chain can be just as disruptive as a hurricane or flood. One of the most advanced supply chain risk management strategies is leveraging financial tools to buffer against economic shocks. This strategy involves using tools like supply chain finance programs and assessing your own risk transfer mechanisms to strengthen suppliers and protect your balance sheet.

When a critical supplier faces a cash flow crisis, it can lead to production delays or even insolvency, directly impacting your operations. By implementing a financial strategy, a Texas-based manufacturer can provide its key suppliers with access to early payments at favorable rates, ensuring their stability. This proactive financial support strengthens the entire network against disruptions, whether they stem from market volatility or the financial aftershocks of a severe weather event.

How to Implement Financial Risk Mitigation

A robust financial strategy requires collaboration with financial institutions and a clear understanding of your supply chain's specific vulnerabilities. For instance, a large agricultural cooperative in the Texas Panhandle could implement a supplier financing program to help smaller farms manage cash flow during unpredictable growing seasons. This ensures a stable supply of raw materials, even if a localized drought impacts a portion of their supplier base.

To implement this effectively, consider these actionable steps:

- Regularly monitor key financial health indicators for all critical suppliers.

- Work with financial partners to design programs like reverse factoring that benefit both you and your suppliers.

- Assess your risk transfer strategy to understand how existing business interruption or contingent business interruption policies cover weather-related events.

- Establish early warning systems to detect signs of financial distress in your supply chain.

It is important to note that the information provided is for educational purposes only. ClimateRiskNow does not offer financial advice or sell insurance products. Companies should consult with qualified financial and insurance professionals to tailor solutions for their specific needs. You can explore a deeper analysis of related risk protection by reading about the role of equipment breakdown insurance on climaterisknow.com.

9. Agile and Flexible Supply Chain Design

In an era of market volatility and unpredictable disruptions, a rigid supply chain can be a significant liability. One of the most forward-thinking supply chain risk management strategies is creating an agile and flexible design. This approach builds adaptability directly into operations, enabling rapid adjustments to demand shifts, material shortages, or sudden logistical challenges like those caused by severe weather events in Texas.

An agile supply chain is not just about speed; it's about responsiveness. When a key transportation route is closed due to flooding, or an unexpected heatwave affects production capacity, a flexible system can reconfigure itself quickly. For a Texas-based manufacturing firm, this could mean shifting production between facilities or rerouting shipments through less-affected hubs to maintain delivery schedules and minimize customer impact.

How to Implement an Agile and Flexible Design

Building agility requires a strategic shift from a purely cost-focused model to one that values responsiveness and resilience. For example, a petrochemical company might invest in dual-use infrastructure that can process different types of crude oil, allowing it to adapt to supply shifts caused by disruptions at a specific oil field or port. This flexibility ensures operational continuity in a volatile market.

To effectively implement this strategy, Texas businesses should consider these actionable steps:

- Implement postponement strategies, delaying final product customization until the last possible moment to better match real-time demand.

- Develop cross-functional teams empowered to make rapid, data-driven decisions during a disruption.

- Invest in flexible manufacturing technologies that can quickly switch between different product lines or specifications.

- Create modular product and process designs that allow for easier reconfiguration and component substitution.

By embedding flexibility into the core design of the supply chain, companies can pivot faster than competitors when faced with operational hurdles. This proactive stance ensures the business can absorb shocks and capitalize on opportunities that arise from market instability.

Supply Chain Risk Management Strategies Comparison

| Strategy | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Supplier Diversification | High - managing multiple suppliers and contracts | Significant - multiple supplier relationships, monitoring | Reduced disruption risk (~30%), improved pricing | Companies needing supply risk mitigation and competitive sourcing | Reduced single-supplier dependency, enhanced negotiating power, supply security |

| Supply Chain Visibility & Monitoring | High - technology integration and system coordination | High - IoT, RFID, AI analytics infrastructure | Early disruption detection, data-driven decisions | Complex supply chains requiring real-time tracking and quality control | Proactive risk management, improved inventory control, better customer service |

| Demand Forecasting and Planning | Moderate to High - requires data analytics capabilities | Moderate - data collection, analytics tools | Improved demand accuracy, reduced inventory costs | Businesses aiming to optimize inventory and reduce bullwhip effect | Lower carrying costs, better resource utilization, enhanced supplier collaboration |

| Strategic Safety Stock Management | Moderate - requires advanced inventory systems | Moderate - inventory investments, forecasting integration | Reduced stockouts, buffer against variability | Organizations with variable demand or supply lead times | Improved service levels, disruption buffer, reduced expediting costs |

| Business Continuity & Disaster Recovery | High - comprehensive planning across functions | High - risk assessments, backup systems, training | Minimized downtime, faster recovery | Companies requiring operational resilience from various disruptions | Enhanced organizational resilience, stakeholder confidence, reduced recovery costs |

| Supplier Relationship Management (SRM) | High - governance, collaboration structures | High - time and resources for partnership management | Improved supplier performance and innovation | Strategic sourcing requiring long-term supplier partnerships | Stronger supplier alignment, innovation, risk reduction, cost savings |

| Geographic Diversification & Nearshoring | High - managing multi-location operations | High - multiple production sites and local expertise | Lower regional risk, improved responsiveness, cost control | Firms seeking risk reduction via regional spread and nearshoring | Reduced regional disruptions, lower transport costs, better market access |

| Financial Risk Mitigation Tools | Moderate to High - financial program management | Moderate to High - financing, professional consultation | Enhanced supplier financial stability, risk mitigation | Companies managing financial risks and supplier liquidity | Improved cash flow, supplier stability, risk protection |

| Agile and Flexible Supply Chain Design | High - flexible systems and rapid decision-making | High - investment in flexible capacity and workforce | Fast response to change, customization, reduced inventory | Businesses facing volatile demand and market shifts | Rapid adaptability, customer satisfaction, asset utilization |

From Strategy to Action: Building a Weather-Ready Enterprise

The journey toward a resilient supply chain is not a destination but a continuous cycle of assessment, preparation, and adaptation. We have explored a range of essential supply chain risk management strategies, from diversifying suppliers and enhancing visibility to implementing agile designs and strategic safety stocks. For business leaders in Texas, a state known for its dynamic economy and equally dynamic weather, these strategies are not abstract concepts. They are the building blocks of operational durability and long-term competitive advantage.

The central theme connecting these disparate tactics is the power of proactive, data-driven decision-making. Waiting for a hurricane to make landfall or a sudden freeze to cripple the power grid is a reactive stance that guarantees disruption. A proactive approach, however, transforms risk from an uncontrollable threat into a manageable variable. This requires moving beyond generalized weather forecasts and embracing localized, asset-specific intelligence that quantifies your unique vulnerabilities.

Synthesizing Strategy into a Resilient Framework

The most effective approach combines several of the strategies discussed into a cohesive, multi-layered defense.

- Foundation of Visibility: You cannot manage what you cannot see. Implementing robust monitoring and visibility tools (Strategy #2) is the non-negotiable first step. This provides the real-time data needed to make informed decisions when disruptions occur.

- Structural Flexibility: Geographic diversification, nearshoring (Strategy #7), and agile supply chain design (Strategy #9) create a system that can bend without breaking. These structural choices reduce dependence on any single node or transportation corridor, providing alternative pathways when a primary route is compromised.

- Collaborative Strength: Strong supplier relationships (Strategy #6) are a force multiplier. When partners are treated as integral parts of your operational ecosystem, they are more likely to collaborate on contingency plans, share risk information, and prioritize your needs during a crisis.

- Strategic Buffers: Intelligent demand forecasting (Strategy #3) and strategic safety stock management (Strategy #4) act as crucial shock absorbers. These buffers buy you valuable time to activate your business continuity plans (Strategy #5) and adapt to sudden shifts in supply or demand.

Ultimately, mastering these supply chain risk management strategies allows your organization to do more than just survive extreme weather events. It enables you to recover faster, maintain customer trust, and potentially capture market share while competitors struggle to restart their operations. By embedding resilience into your company’s DNA, you safeguard your assets, protect your people, and secure your future in an increasingly unpredictable climate. The initial investment in understanding your specific risks is the most critical one you can make.

Ready to move from strategy to action? Quantify your organization's precise weather-related risks with Sentinel Shield. Our platform provides the granular, site-specific intelligence you need to build a truly resilient supply chain. Discover your vulnerabilities and start building a more secure future today.