For manufacturers across Texas's key industries—from Energy & Petrochemical to Agriculture and Construction—quality assurance (QA) isn't just a final inspection. It’s a core operational strategy—a continuous, proactive process baked into every step of production. This is how you mitigate operational risk, protect your brand, and build resilience against disruptions, including those from the state's notoriously extreme weather events.

Why Quality Assurance Is Your Competitive Edge

Too many leaders still see manufacturing QA as a cost center—a final exam a product has to pass before it ships. That view misses the real picture entirely. A modern QA framework is an engine for growth and operational stability. It shifts the focus from simply catching defects to preventing them from ever happening.

This proactive mindset is non-negotiable in Texas's high-stakes industries. For an agriculture equipment maker in the Panhandle or a petrochemical plant on the Gulf Coast, a single failed component can trigger costly downtime, create serious safety hazards, and do lasting damage to your reputation. A quality failure during an extreme weather event, such as a hurricane or deep freeze, can escalate a manageable situation into a catastrophic one.

The Financial and Reputational Risks of Poor Quality

The fallout from poor quality isn't just theoretical; it hits the bottom line hard. Since 2018, the manufacturing industry has seen a stunning 115% spike in product recalls, especially in critical fields. Those recalls come with a massive price tag, costing companies an estimated $5 billion globally each year. This trend is a clear warning sign that outdated quality systems are a significant business risk.

A robust quality assurance system is built on several key pillars that work together. From top-down leadership to on-the-ground process controls, each component is essential for building a culture of quality that can withstand operational pressures.

Key Pillars of a Proactive Quality Assurance System

| Pillar | Description | Business Impact for Texas Industries |

|---|---|---|

| Leadership & Culture | Executive commitment to a "quality-first" mindset that permeates every level of the organization. | Ensures teams remain vigilant, from an assembly line in a Dallas factory to the control room of a Houston refinery, especially during high-stress events. |

| Process Control | Implementing strict, repeatable procedures and controls at every stage of production to minimize variability. | Critical for ensuring consistent product performance, whether it's an aerospace part or a batch of chemicals facing extreme temperature fluctuations. |

| Supplier Quality | Rigorously vetting and monitoring suppliers to ensure raw materials and components meet exacting standards. | Protects against supply chain disruptions, a common consequence of weather events, and prevents subpar materials from entering the production flow. |

| Corrective & Preventive Action (CAPA) | A systematic approach to investigating root causes of issues and implementing changes to prevent recurrence. | A non-negotiable for high-risk sectors like energy and construction, turning every mistake into a lesson that strengthens operational resilience. |

A well-integrated system built on these pillars transforms quality from a departmental task into a company-wide competitive advantage.

Beyond Defect Detection: A Strategic Advantage

When you get QA right, the benefits are felt across the entire business. It's about building predictability and resilience directly into your day-to-day operations. By focusing on process consistency, you don’t just make a better product—you also become more efficient, a key part of managing operational risk. Every step, from sourcing materials to final delivery, is optimized for excellence.

A solid quality assurance program delivers several key outcomes:

- Enhanced Customer Loyalty: When you consistently deliver reliable products, you build trust. That trust creates a loyal customer base that's far less sensitive to price.

- Improved Operational Efficiency: QA naturally uncovers and corrects process bottlenecks. This reduces waste, minimizes rework, and ultimately lowers your production costs. We explore this further in our guide on operational efficiency improvement.

- Greater Financial Stability: By preventing defects and recalls, you shield your bottom line from surprise expenses and the staggering cost of fixing large-scale mistakes after the fact.

Inside a Modern Quality Assurance Framework

A top-tier quality assurance program isn't something that just happens. It’s built on a foundation of deliberate, proven processes. For Texas businesses, mastering these methods is what turns QA from a simple final check into a powerful engine for operational excellence. Think of it as your strategic blueprint for getting it right, every single time.

At its heart, a modern QA framework is all about structured checks at every critical step of production. This isn't about finding mistakes at the end—it's about preventing them from ever happening in the first place.

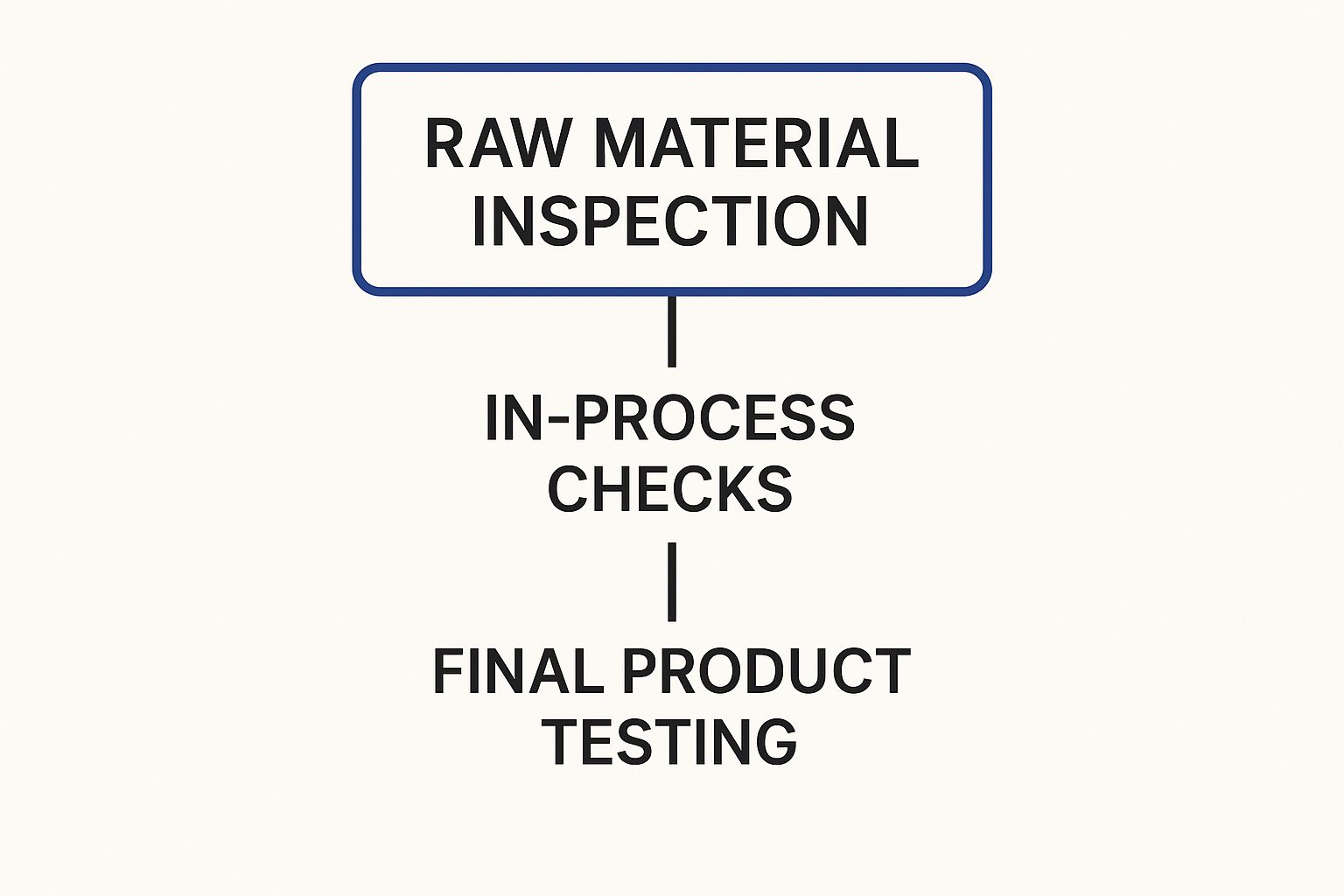

This is how you catch potential issues early, long before they become expensive problems down the line. The image below breaks down the three fundamental levels of this process, showing how quality is layered into the entire production lifecycle.

As you can see, quality isn't a single event. It’s a continuous flow, from the moment raw materials arrive to the final validation of finished goods. Let’s dig into the key methodologies that bring this framework to life.

Core Methodologies For Texas Manufacturers

Several powerful tools form the backbone of modern quality assurance. While the names might sound technical, their applications are incredibly practical and have a direct impact on your bottom line. Three of the most essential are Statistical Process Control (SPC), Failure Mode and Effects Analysis (FMEA), and Total Quality Management (TQM).

Total Quality Management (TQM) is a management philosophy where quality becomes everyone's job. It pulls together every part of the business—from design and manufacturing to sales and service—to focus on meeting customer needs and hitting company goals.

This mindset is a perfect fit for Texas's diverse industrial landscape. It ensures that everyone, from a worker in the Permian Basin to a logistics coordinator in Dallas, knows exactly how they contribute to a quality outcome.

Applying FMEA to Mitigate Critical Risks

Failure Mode and Effects Analysis (FMEA) is a proactive risk assessment tool. Instead of waiting for things to break, FMEA helps you get ahead of potential failures. Your team brainstorms what could go wrong, figures out how bad the fallout would be, and puts controls in place to stop it from happening.

- Identify Potential Failures: Pinpoint what could possibly go wrong in a process or product, considering operational stressors like extreme heat.

- Analyze the Effects: Figure out the consequences if that failure actually occurs.

- Prioritize the Risks: Score each risk based on its severity, likelihood of happening, and how easily you can detect it.

- Implement Preventive Actions: Develop concrete strategies to eliminate or reduce the highest-priority risks.

For a Texas-based oil and gas equipment manufacturer, this is mission-critical. An engineering team using FMEA might identify that a specific valve is prone to failure under extreme heat. Armed with that knowledge, they can switch to a more resilient material or add a cooling mechanism, preventing a catastrophic failure on an offshore rig during a summer heatwave. This kind of deep-dive analysis lines up with the principles found in more comprehensive risk assessment methodologies.

Using SPC for Process Consistency

Statistical Process Control (SPC) is all about using data to monitor and control your processes. It helps you tell the difference between normal, acceptable variations and "special cause" variations that signal a real problem. By tracking key metrics on control charts, your team can see when a process is starting to drift out of spec and step in before any defects are made.

Think about a construction materials supplier in Houston. They could use SPC to monitor the compressive strength of their concrete batches. If the data points on their control chart start trending downward—perhaps due to high humidity affecting raw materials—it’s a clear signal to investigate. This lets them fix the problem proactively, ensuring every batch meets tough safety and performance standards without a single dollar wasted on rework.

To get a deeper look at the strategies inside a well-built quality system, you can explore the insights on applying a Quality Assurance in Manufacturing: A Framework for Excellence. These frameworks offer a structured path to turning quality principles into real-world business results.

Navigating Key Quality and Regulatory Standards

For manufacturers in Texas, getting a handle on quality standards isn't just about checking a box for compliance. It's a strategic play that opens up new markets, builds unshakeable customer trust, and makes your entire operation more resilient. Think of these frameworks as a proven roadmap for turning abstract goals about "quality" into concrete, repeatable processes.

These standards essentially create a universal language for quality. When your business gets certified, you’re sending a clear signal to partners and customers. You're telling them your manufacturing quality assurance system meets a tough, internationally respected benchmark. This isn't about getting buried in paperwork; it's about sharpening every single process to gain a real competitive edge.

ISO 9001: The Cornerstone of Quality

At the heart of it all is ISO 9001, the world’s most recognized standard for quality management systems (QMS). It offers a flexible framework that can be adapted to any organization. The whole thing is built around a few core ideas: a sharp focus on the customer, engaged leadership, and a constant drive to get better.

Implementing ISO 9001 helps put your processes down on paper, locking in consistency from the moment raw materials arrive to the final product delivery. A 2021 survey showed that businesses with ISO 9001 certification saw a 41% improvement in customer satisfaction and a 35% reduction in product defects. It creates the solid foundation you need before layering on more specialized, industry-specific standards.

Sector-Specific Standards for Texas Industries

While ISO 9001 is a powerful starting point, Texas's biggest industries often need more specialized certifications to deal with their unique operational and regulatory headaches. Adopting these standards shows you're committed to being the best in your specific field.

Here are a few that really matter in Texas:

- API Q1 for Energy & Petrochemical: The American Petroleum Institute (API) Specification Q1 is the gold standard for anyone making equipment for the oil and gas industry. It covers everything in ISO 9001 but adds much stricter rules for risk assessment, contingency planning, and managing your supply chain—all absolutely critical for thriving in the state's demanding energy sector.

- AS9100 for Aerospace: For the state's booming aerospace and defense contractors, AS9100 isn't optional. It builds on ISO 9001 with specific requirements for product safety, configuration management, and preventing counterfeit parts from ever entering the supply chain.

- SQF/BRC for Agriculture & Food: For Texas's vast agriculture sector, standards like the Safe Quality Food (SQF) Program or BRC Global Standards are vital for ensuring food safety and quality from farm to table.

These certifications do a lot more than just help you land new contracts. They enforce a level of operational discipline that makes your whole business stronger from the inside out.

Adopting rigorous quality standards is a fundamental risk management strategy. It helps reduce legal exposure from product failures and ensures operational continuity by embedding resilience into every facet of production, including emergency preparedness.

The Strategic Value of Certification

Going after and maintaining these certifications delivers a clear return on your investment. It systematically cuts down on the chances of making costly mistakes, dealing with recalls, or facing operational shutdowns. When you standardize your procedures, you create a more predictable and controlled manufacturing environment. That consistency is key not just for everyday work, but for bouncing back quickly when things go wrong.

These frameworks also help businesses navigate the maze of local and federal regulations, such as those from TCEQ or OSHA, making sure every safety and compliance rule is met. This proactive approach is a core part of any smart risk mitigation plan. For instance, having documented and audited safety procedures directly supports your company's broader safety protocols, like the ones discussed in our guide to emergency evacuation procedures. By choosing the right certifications for your business goals, you're making a direct investment in long-term resilience and your position as a market leader.

Disclaimer: The information provided in this article is for educational and informational purposes only. ClimateRiskNow does not sell insurance or financial products and this content should not be interpreted as financial advice or an insurance recommendation.

How Technology Is Changing Quality Assurance

Technology is fundamentally reshaping quality assurance in manufacturing. The whole game is shifting from a reactive, after-the-fact inspection to a predictive, proactive strategy. For industries here in Texas and beyond, new innovations are hitting the factory floor, allowing teams to catch potential problems with incredible speed and accuracy. This isn't just about new gadgets; it's about making smarter, data-driven decisions that have a real impact on the bottom line.

The days of relying solely on a clipboard and a pair of sharp eyes are coming to an end. Modern tools give us a level of insight that was previously unimaginable, turning quality control from a necessary headache into a serious competitive advantage. These systems work around the clock, spotting patterns and flagging tiny deviations long before they turn into a pile of expensive scrap.

From Manual Checks to Smart Systems

The heart of this change is the integration of powerful digital tools right onto the production line. Three technologies, in particular, are leading the charge: Artificial Intelligence (AI) for predictive analytics, Internet of Things (IoT) sensors for real-time monitoring, and automated visual inspections for precision that never gets tired. When you put them together, you get a connected system where quality is a living, breathing part of the process.

This move away from traditional methods is a big deal. It pulls operations out of a constant state of firefighting and into a place where you're actively preventing problems before they start—a critical shift for any high-stakes manufacturing environment.

Comparing Traditional vs Tech-Enabled QA Methods

Looking at the old way versus the new way side-by-side really highlights the difference. The contrast shows just how much leverage modern tools provide.

| QA Aspect | Traditional Method | Tech-Enabled Method | Key Benefit |

| :--- | :--- | :--- |

| Defect Detection | Manual, visual inspection by human operators. | AI-powered cameras inspect every single unit automatically. | Higher Accuracy: Eliminates human error and fatigue, catching microscopic flaws. |

| Process Monitoring | Periodic manual checks of machine settings. | IoT sensors stream live data on temperature, pressure, humidity, etc. | Real-Time Control: Instantly alerts teams to out-of-spec conditions, preventing waste. |

| Root Cause Analysis| Based on limited data and anecdotal evidence. | Predictive analytics models analyze historical data to find root causes. | Deeper Insights: Identifies hidden patterns to solve quality issues for good. |

What we're seeing is a fundamental upgrade in capability across the board, from finding flaws to preventing them in the first place.

The Power of Predictive Quality and Real-Time Data

Imagine a system that doesn't just tell you a part is bad. Imagine a system that tells you a batch is going to be bad—before you even make it. That's the power of AI in predictive quality analytics. By digging through historical production data, machine performance metrics, and even environmental conditions like ambient factory temperature, AI models can pinpoint the subtle factors that lead to quality issues.

At the same time, IoT sensors act like the factory's nervous system. These small devices get attached to machinery, constantly collecting and sending data on everything from vibration and temperature to energy use. This constant stream of information makes real-time process control possible, ensuring every machine is humming along within its optimal parameters. It is a powerful tool for Texas industries where environmental conditions can change rapidly.

The global market for these services is blowing up, which tells you how fast this is being adopted. Valued at roughly $5.3 billion, the market is expected to more than double to around $12.9 billion by 2031. This explosive growth is all about manufacturers demanding more precision and efficiency to compete. You can discover more insights about AI-enhanced QA in manufacturing here.

Case Study: A Texas Company Slashes Defects

To see what this looks like on the ground, let’s look at a Texas-based agricultural equipment company. They were struggling with inconsistent quality and a high scrap rate on a critical component. So, they brought in an AI-powered automated visual inspection system. They installed high-resolution cameras on the assembly line to scan each part, while the AI algorithm—trained on thousands of images—learned to spot even the tiniest imperfections.

The results were immediate and massive. Within six months, the company cut its defect rate for that component by over 85%. The system didn't just catch flaws more accurately than a human inspector; it also provided data that helped engineers trace the problem back to a specific machine that needed to be recalibrated.

This story makes the business case crystal clear. The investment paid for itself by cutting down on waste, reducing the labor costs tied to manual inspection, and making their product much more reliable. By embracing technology, the company didn't just fix a pressing quality issue—they built a stronger, more resilient production process for the future.

Building an Unbreakable Quality Culture

The most advanced tools and perfectly written processes can only get you so far. Real operational excellence happens when a commitment to quality becomes part of your company’s DNA. It’s about creating a culture where every single person, from the C-suite to the shop floor, takes ownership of the final product.

Think of it like a championship sports team. The playbook is essential, but victory comes from the team’s shared mindset and relentless drive to perform. A strong quality culture works the same way, turning passive compliance into active, engaged problem-solving.

Securing Leadership Buy-In

A quality-first mindset has to start at the top. When executives consistently talk about and prioritize quality, it sends a powerful signal that echoes through the entire organization. This is about more than just signing off on a budget; it's about actively championing the cause.

Leadership’s commitment is shown through action. For a construction firm in Dallas, it might be the CEO regularly walking job sites to check on safety and quality. For a petrochemical plant manager in Houston, it could mean publicly recognizing teams that spot and fix potential issues before they become real problems.

The most effective quality cultures are built on trust. This means creating an environment where people feel safe to report potential issues without fear of blame. When you encourage people to speak up, you get priceless on-the-ground insights that stop small errors from turning into major failures.

This kind of open communication is critical. It transforms your entire workforce into an extension of the QA team, creating a vigilant network that protects your operations and your reputation.

Empowering Employees Through Continuous Training

A well-trained workforce is a confident and capable one. But good training isn't a one-and-done orientation—it's an ongoing process that keeps skills sharp and knowledge current. This is especially vital in Texas's diverse industrial sectors, where technology and processes are always evolving.

For instance, a logistics company can run regular training on proper handling procedures to cut down on in-transit damage. In a manufacturing plant, continuous education makes sure machine operators are experts at not just running their equipment, but also spotting the subtle signs that a process is drifting out of spec.

The goal is to give every employee three key things:

- The "Why" Behind the Rules: Help them see how their specific actions directly impact product safety, customer satisfaction, and the company's bottom line.

- The Skills to Succeed: Provide hands-on training that builds real competence and confidence.

- The Authority to Act: Empower them to pause a process or flag a concern if they see something that isn’t right.

The Role of Immersive Technology in Training

Modern tech is completely changing how this training gets done. Immersive and digital tools are shaking up quality assurance in manufacturing by transforming how we train people and detect defects. In fact, over 3,500 companies with annual revenues over $200 million have invested heavily in augmented reality (AR) and virtual reality (VR) training. These tools are proven to sharpen operator skills and slash human error in complex tasks.

This kind of immersive technology makes quality assurance more efficient and accurate, and it helps bridge the gap for companies with production facilities spread across different locations. You can see more on these new trends in quality management.

Imagine a new technician learning to assemble a complex piece of equipment for a wind turbine. With an AR headset, digital instructions are overlaid directly onto the physical parts in front of them. This makes training more engaging, boosts knowledge retention, and dramatically reduces the odds of an error—building a more skilled and quality-driven workforce from day one.

Your Roadmap to a Rock-Solid QA System

Alright, so you understand the principles of manufacturing quality assurance. The next big question is: how do you actually build a system that works? It requires a deliberate plan, not a frantic overhaul.

Think of this as your playbook for making quality a core part of your operation. We’re going to walk through a phased approach that builds momentum and gets you real, measurable wins without tearing everything down at once. It all starts with taking an honest look at where you are today.

Start with an Honest Assessment

Before you can build anything new, you have to know the ground you're standing on. The first step is a no-holds-barred assessment of your current quality processes—or the lack of them. This means digging into the hard data on defect rates, customer returns, and production bottlenecks.

A thorough review helps you connect the dots and find those recurring problems. For example, a construction materials supplier in Texas might discover that one specific raw material is constantly tied to product failures down the line. This initial analysis is absolutely critical for setting a clear direction. A structured approach, like the one in our business impact analysis template, provides a solid framework for this kind of evaluation.

Set Clear, Measurable Goals

Once you have a baseline, you need to define what "better" actually looks like. Your objectives have to be specific, measurable, achievable, relevant, and time-bound (SMART). A vague goal like "improve quality" is a recipe for going nowhere.

Instead, get granular with concrete targets. Something like:

- Cut final assembly defects by 15% within the next six months.

- Bring down customer warranty claims by 10% this fiscal year.

- Push the first-pass yield on Production Line 3 up to 98% by the end of this quarter.

These kinds of precise goals get your teams aligned and give you clear benchmarks to measure yourself against. It’s how you turn quality from a fuzzy concept into a hard business objective.

Launch a Pilot Program

Don't try to boil the ocean. Instead of a massive, company-wide rollout that invites chaos, start small with a focused pilot program. Pick a single product line or one production area where you can test-drive your new QA processes in a controlled setting.

This approach minimizes risk and lets you work out the kinks, gather real-world data, and train a core team that can become champions for the new system. A successful pilot acts as a powerful proof of concept, making it much easier to get buy-in for a broader implementation. It builds confidence and momentum, setting the stage for a full-scale win. If you're looking for more practical strategies, check out a comprehensive guide to manufacturing quality improvement for some great insights.

Disclaimer: This article is for educational purposes only. ClimateRiskNow does not sell insurance or financial products, and the information provided should not be interpreted as financial advice or an insurance recommendation. To transform complex weather data into a clear risk management strategy for your Texas-based operations, request a demo of Sentinel Shield at https://www.climaterisknow.com.