For business decision-makers in Texas, a hurricane is not merely a weather event—it is a complex operational threat with cascading impacts across the enterprise. The risk extends far beyond high winds and coastal flooding, disrupting supply chains, crippling critical infrastructure, and endangering the workforce.

Reactive measures are no longer sufficient. Mitigating the impact of a hurricane natural disaster requires a proactive, data-driven risk management strategy.

Understanding Hurricane Risk for Texas Industries

For executives in key Texas sectors—Energy & Petrochemical, Manufacturing, Logistics, Agriculture, and Construction—viewing a hurricane as just a storm is a significant miscalculation. Gulf Coast storms are increasing in frequency and intensity, meaning a single event can trigger a chain reaction of operational failures.

According to NOAA, in 2023 alone, the U.S. experienced 28 separate billion-dollar weather and climate disasters. This statistic underscores the immense financial stakes for unprepared businesses.

This guide provides actionable, data-driven insights to help companies assess, prepare for, and mitigate operational risks from these extreme weather events. The focus is on strategic preparedness, not insurance products.

- Operational Resilience: We will explore practical methods to protect facilities, secure supply chains, and ensure employee safety.

- Data-Driven Decisions: Learn how to leverage historical weather data and predictive analytics to inform strategic decisions well before a storm makes landfall.

- Industry-Specific Threats: We will analyze the unique vulnerabilities facing Texas's core industries, from coastal refineries to inland distribution hubs.

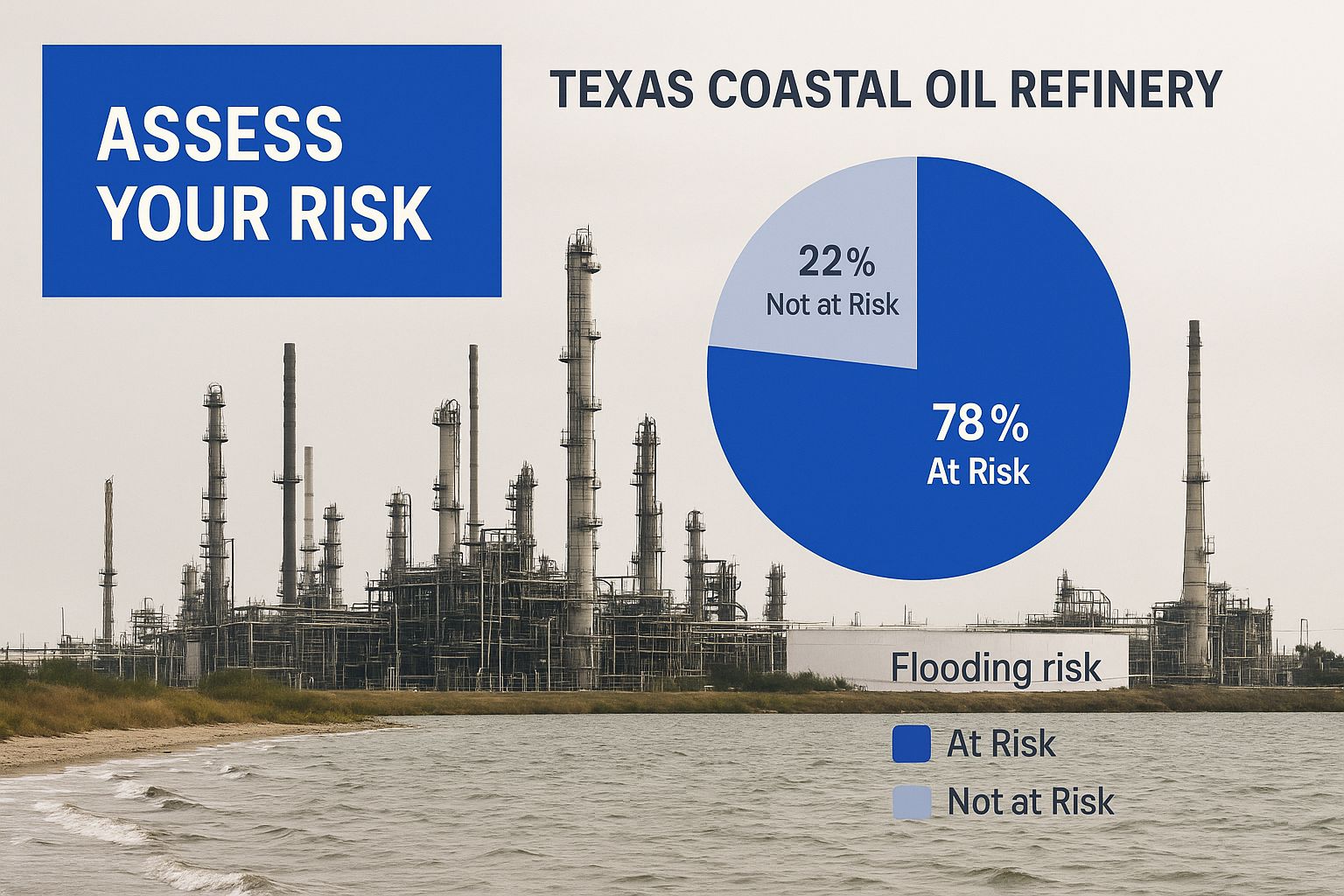

The first step is a facility-level risk assessment. Each asset possesses a unique exposure profile based on its location and operational function.

This image illustrates a critical point: a petrochemical plant on the coast faces a different threat landscape than a logistics warehouse in Houston. Each risk profile must be quantified. For a deeper analysis of asset-level threats, you can explore our detailed review of NOAA data for Texas facilities.

Disclaimer: ClimateRiskNow does not sell insurance or financial products. The information provided in this article is for educational purposes only and should not be construed as financial or insurance advice. Organizations should consult with qualified professionals for guidance specific to their needs.

It is also important for risk managers to understand that many standard commercial property policies exclude flood damage. A clear understanding of the differences between policies like flood insurance vs homeowners insurance is fundamental to developing a resilient operational strategy, though this guide does not recommend specific products.

How a Hurricane Impacts Business Operations

While high winds are a primary concern, the full spectrum of operational risk from a hurricane natural disaster is far more complex. An effective preparedness plan must account for the specific, tangible threats each component of a storm poses to Texas businesses.

Often, the most destructive elements of a hurricane are water-related. These threats can have a domino effect, creating a chain reaction of interconnected problems that can halt operations for weeks or months.

Beyond Wind Damage: Direct Operational Threats

A hurricane is a system of hazards, and for businesses in Texas, the most significant operational threats often extend beyond structural wind damage.

- Storm Surge: This wall of water pushed ashore by the storm is catastrophic for coastal facilities. A 15-foot storm surge can inundate petrochemical plants, ports, and manufacturing sites, destroying critical equipment, contaminating inventory, and forcing long-term shutdowns.

- Inland Flooding: Hurricanes can stall and deposit extreme rainfall totals hundreds of miles from the coast. Hurricane Harvey demonstrated this with rainfall measured in feet, not inches, submerging distribution centers, paralyzing highway systems, and destroying agricultural assets far from the point of landfall.

- Tornadic Activity: As hurricanes move inland and weaken, they frequently spawn tornadoes. These intense, localized events can cause severe, unpredictable damage to construction sites, vehicle fleets, and manufacturing plants with minimal warning.

These elements combine to create an untenable operating environment. A facility that withstands high winds can still be rendered inoperable by a flooded access road or a regional power grid failure.

A common mistake is underestimating water-related risks. Catastrophic flooding from storm surge and torrential rainfall is often the primary driver of long-term operational disruption and financial loss.

Sector-Specific Vulnerabilities in Texas

A hurricane's impact is not uniform; it varies based on industry and geography. A manufacturer in Dallas faces different challenges than a refinery in Corpus Christi, though both are exposed to significant risk.

For example, a logistics company relies on clear roads and operational ports. Widespread flooding can sever major arteries like I-10, stranding inventory and bringing supply chains to a halt. This disruption impacts not only the logistics provider but also the manufacturers and retailers dependent on those deliveries.

The agriculture sector is impacted on multiple fronts. Coastal farms can be devastated by saltwater intrusion from storm surge, while inland operations face crop loss and topsoil erosion from flooding. These are not single-season issues; they have long-term consequences for production and profitability.

To manage these distinct challenges, it is essential to break down how a hurricane's primary threats impact key Texas industries.

Hurricane Threats to Key Texas Industries

The table below outlines the primary threats from a hurricane and their specific operational consequences for major sectors across Texas.

| Threat | Impact on Energy and Petrochemical | Impact on Manufacturing and Logistics | Impact on Agriculture and Construction |

|---|---|---|---|

| Storm Surge | Inundation of refineries and storage tanks, critical equipment damage, risk of chemical spills. | Port closures halting imports/exports, damage to coastal warehouses and distribution hubs. | Contamination of coastal farmland with saltwater, destruction of aquaculture operations. |

| Inland Flooding | Disruption to pipeline operations, restricted access for personnel and maintenance crews. | Paralysis of ground transportation, flooded facilities, destroyed inventory and vehicle fleets. | Widespread crop loss, soil erosion, delayed planting seasons, submerged construction sites. |

| Wind & Tornadoes | Structural damage to cooling towers and processing units, power grid failure causing shutdowns. | Roof and structural damage to plants and warehouses, risk to exposed materials and equipment. | Destruction of buildings under construction, damage to farm structures and irrigation systems. |

Pinpointing these specific vulnerabilities is the crucial first step toward building an operational strategy that is truly resilient. It moves the conversation from just "getting through the storm" to proactively managing the cascading business impacts that follow.

Learning from Texas Hurricane History

Reviewing historical hurricane impacts in Texas transforms theoretical risks into tangible case studies. Past storms offer invaluable lessons on operational successes and failures, providing a data-rich foundation for contemporary business decisions. By analyzing the cascading consequences of these events, we can identify critical vulnerabilities.

Media reports often focus on wind speeds and storm categories. For a business, however, the real impact is measured in months of lost production, fractured supply chains, and economic damages that persist for years. Events like Hurricane Ike (2008) and Hurricane Harvey (2017) are stark reminders of the high operational and financial stakes.

Hurricane Harvey: A Case Study in Cascading Failures

Hurricane Harvey in 2017 was a watershed event for Texas. The primary driver of damage was not wind, but water. The storm stalled over the Houston metropolitan area, depositing over 50 inches of rain in some locations, resulting in catastrophic flooding that paralyzed a major U.S. economic hub.

For businesses, the impacts were immediate and created a domino effect across operations:

- Supply Chain Paralysis: Major transportation arteries like Interstate 10 were submerged, severing critical logistics corridors. This prevented the inflow of raw materials and the outflow of finished products, with global ripple effects.

- Infrastructure Damage: Floodwaters inundated industrial facilities, disabling heavy machinery, destroying billions in inventory, and contaminating entire sites. Many plants remained offline for months due to the failure of basic infrastructure—roads, power, and water—not direct storm damage.

- Workforce Disruption: Employee availability became a critical issue as homes flooded and roads became impassable. This exposed a key vulnerability: a business cannot operate if its workforce is displaced and addressing personal crises.

The economic cost of these events is staggering. Hurricanes consistently rank among the costliest natural disasters, with damages often reaching tens of billions. Hurricane Harvey alone inflicted an estimated $125 billion in damages. To contextualize the financial scale, you can find detailed reports on the costliest hurricanes in U.S. history.

Strategic Lessons from Past Storms

Retrospective analysis of these storms provides executives in Energy, Manufacturing, and Construction with a clear blueprint of potential impacts. A key lesson from Hurricane Ike was the vulnerability of the Houston Ship Channel to storm surge—a direct threat to the nation’s petrochemical sector. The near-miss underscored the need for enhanced coastal defenses and hardened infrastructure.

Hurricane Harvey, conversely, exposed the immense risk of inland flooding. Companies far from the coast learned that their operations were equally vulnerable when record rainfall shut down an entire region. These storms demonstrate that a comprehensive risk strategy must account for every facet of a hurricane natural disaster.

The most resilient organizations learn from the failures of others. Post-event analyses show that companies recovering fastest were those with pre-staged resources, redundant communication channels, and flexible logistics plans.

It is critical to move from historical analysis to proactive planning. These storms reveal exactly what can go wrong, allowing you to stress-test your own operational vulnerabilities. For a deeper dive, review the operational lessons learned from Hurricane Harvey and apply those insights to your strategy.

The objective is not merely to survive the next storm, but to build an operational model that can withstand it and resume activities faster than the competition.

Conducting an Operational Vulnerability Assessment

Historical knowledge is foundational, but building operational resilience requires an inward focus. The next step is to systematically identify your company’s unique vulnerabilities before a hurricane does. A thorough operational vulnerability assessment moves an organization from theory to action, providing a clear roadmap for targeted defensive investments.

This is not a generic checklist exercise but a deep analysis of every operational component, designed to answer difficult questions.

The goal is to uncover hidden dependencies and single points of failure that could halt business operations during a major storm. This process provides leadership with the hard data needed to make informed, strategic risk mitigation decisions.

Evaluating Physical Infrastructure and Assets

The most direct risk from a hurricane is to physical locations. For manufacturing plants, petrochemical facilities, and construction sites, the structural integrity of buildings is paramount. However, a proper assessment must go deeper than the facility walls.

Critical questions must be addressed. Are key facilities located in a known storm surge zone or a 100-year floodplain? What is the certified wind rating of critical buildings? Answering these questions requires mapping assets against known hazard zones—a fundamental first step in quantifying direct physical risk.

Mapping Supply Chain Dependencies

An intact facility is of little use if raw materials cannot be received or finished products cannot be shipped. Modern supply chains are complex networks of dependencies, and a single hurricane can sever critical links hundreds of miles away. A robust assessment must map dependencies both upstream to suppliers and downstream to logistics partners.

This requires a meticulous map of the entire supply chain:

- Identify Critical Suppliers: Pinpoint Tier 1 and Tier 2 suppliers operating in hurricane-prone regions along the Gulf Coast or in the Southeast.

- Assess Logistics Chokepoints: Analyze dependence on specific ports, highways, and rail lines that are frequently disrupted by storm activity.

- Quantify Single-Source Risks: Determine which essential components or materials are sourced from a single supplier or region, representing a significant vulnerability.

This analysis helps executives understand how a storm impacting Galveston could halt a production line in Dallas. Identifying these weak points in advance allows for the vetting of alternative suppliers or the pre-positioning of key inventory long before a storm forms.

Pinpointing specific weaknesses in your supply chain and infrastructure is the core of a successful vulnerability assessment. It transforms general hurricane preparedness into a targeted, actionable strategy for protecting your operations.

Assessing Workforce and Data Infrastructure

Personnel and data are among a company's most valuable assets, and a hurricane places both at significant risk. An effective assessment must cover the human element and the digital infrastructure that supports operations.

For the workforce, safety and availability are primary concerns. Are there clear communication plans and safety protocols? What percentage of the team resides in flood-prone areas, and how might that impact business resumption?

Data resilience is equally critical. If a primary data center is in a high-risk area, what is the recovery plan if it is offline for an extended period, such as two weeks? Cloud backups are a good start, but the ability to restore operations from those backups under pressure must be tested. To organize this process, use the framework in our detailed Business Impact Analysis template. This structured approach ensures you don’t overlook critical interdependencies.

Building Your Hurricane Preparedness Plan

After a vulnerability assessment identifies key weak points, the insights must be translated into a practical, data-driven hurricane preparedness plan. This should be a living operational playbook that uses advanced weather intelligence to trigger proactive, predetermined actions before a storm makes landfall.

The objective is to shift from a reactive to a proactive posture. Instead of scrambling when a hurricane warning is issued, the organization executes pre-planned actions based on long-range forecasts and risk analytics. This approach differentiates companies that merely survive a storm from those that protect their people, assets, and market share.

Creating Phased Shutdown and Startup Procedures

A costly error is treating storm preparation as a binary on/off switch. A premature shutdown results in lost production, while a delayed one risks catastrophic damage. An effective plan uses a phased approach, tying specific actions to clear, data-driven triggers.

Consider a manufacturing plant on the Gulf Coast. Using long-range forecasts, it can begin pre-positioning critical inventory or engaging alternative suppliers 7-10 days before a potential storm. As the forecast certainty increases, the plan escalates:

- 72 Hours Out: Secure outdoor equipment, test backup generators, and confirm redundant communication channels with key personnel.

- 48 Hours Out: Begin a systematic, controlled shutdown of non-critical production lines, avoiding a last-minute scramble.

- 24 Hours Out: Release non-essential personnel and activate final facility lockdown procedures.

The same logic applies in reverse for post-storm recovery. A phased startup plan ensures operations can be brought back online safely and efficiently by prioritizing damage assessments and critical functions.

Securing Assets and Establishing Redundancy

The plan must detail specific actions to protect physical assets and maintain operational continuity. This extends beyond basic measures to fortifying the entire physical and digital infrastructure.

Key components should include:

- Asset Protection: For a construction site, this involves securing heavy machinery and materials that could become projectiles. For an agricultural operation, it may mean moving livestock to higher ground and protecting irrigation systems.

- Communication Redundancy: Cellular and internet infrastructure are often early casualties. The plan must include redundant channels like satellite phones or a designated out-of-state communication hub for employee check-ins.

- Data Fortification: All critical operational data must be backed up to multiple secure, geographically diverse locations. The plan should also detail the protocol for restoring this data and enabling remote operations if primary facilities are inaccessible.

A logistics company with a data-driven plan can use advanced storm track probabilities to pre-plan alternate routes, diverting shipments away from potential impact zones days in advance. This keeps the supply chain moving while competitors are stuck.

Supporting Your Workforce and Adhering to Regulations

A company's most valuable asset is its workforce. A robust plan must prioritize employee safety and well-being through clear communication protocols, evacuation support where applicable, and post-storm assistance programs.

Furthermore, Texas businesses must adhere to local and federal regulations. Guidelines from the Texas Division of Emergency Management (TDEM) are essential for informing your plan and ensuring compliance, particularly for industries like petrochemicals that handle hazardous materials.

The need for meticulous planning is growing. Data shows a clear trend of increasing intensity in North Atlantic hurricane activity. The Accumulated Cyclone Energy (ACE) Index, a measure of a season's total destructive power, confirms that eight of the ten most active seasons on record have occurred since 1995.

A well-crafted plan provides clarity amid a crisis, empowering teams to act decisively and transform chaos into a structured response. For tactical guidance, our comprehensive hurricane season preparation checklist is a valuable resource.

Creating Long-Term Business Resilience

The ultimate objective is not just to survive the next hurricane, but to embed a proactive, risk-aware culture throughout the organization. Hurricane preparedness should be an ongoing strategic commitment to operational resilience—building a business capable of absorbing the shock of a major storm, recovering faster, and emerging stronger.

When executed correctly, hurricane planning evolves from an operational burden into a competitive advantage. In an era of increasing climate volatility, the ability to maintain operations when competitors cannot is a powerful market differentiator.

The Continuous Cycle of Improvement

Resilience is not a static achievement but a continuous cycle of assessment, planning, and refinement. The most prepared businesses in Texas treat their emergency plans as living documents, constantly updating them with new data and lessons learned from every storm event and near-miss.

This proactive stance is built on core pillars:

- Data-Driven Mitigation: Using historical weather data and predictive analytics to inform decisions, from facility reinforcement to supply chain diversification.

- Thorough Risk Assessments: Regularly revisiting vulnerability assessments to account for operational changes, new assets, or evolving climate threats.

- Strategic Preparedness: Integrating emergency preparedness into core business strategy to ensure it receives necessary leadership buy-in and resources.

The critical shift is to stop viewing preparedness as an expense and start seeing it as an investment in the long-term health and stability of your entire operation.

Building a Resilient Future

Historical data provides essential context. Since record-keeping began in 1851, the Atlantic basin has experienced 1,745 tropical cyclones, with 971 strengthening into hurricanes. This long-term data underscores the persistent nature of this threat.

By integrating these lessons and building a robust continuity plan, you are safeguarding your operations. To ensure comprehensive coverage, the ultimate business continuity planning checklist is an essential resource. A well-documented strategy is the best tool for navigating the disruption of a large-scale event.

Ultimately, building this level of resilience empowers Texas businesses to do more than just survive a hurricane. It enables them to thrive in a challenging environment. For a structured approach, explore our guide to developing a comprehensive business resilience framework.

Common Questions About Hurricane Preparedness

Business leaders across Texas frequently ask key questions as they develop their risk management plans for a hurricane natural disaster. Below are answers to some of the most critical inquiries.

How Far in Advance Should We Start Prepping for a Hurricane?

Effective hurricane preparedness is a year-round commitment, not a seasonal activity. The most resilient companies review emergency plans, update contact lists, and conduct drills during calm weather conditions.

For a specific storm, activation of the plan should begin at least 5-7 days in advance. This is the window when meteorological forecasts provide a reliable indication of a potential track and intensity. This lead time allows for communication with teams, facility securing, and coordination with suppliers and customers without creating panic. The focus should always be on proactive, not reactive, measures.

What's the Single Biggest Mistake Businesses Make?

The most common and costly mistake is focusing on wind risk while underestimating water-related threats.

While high winds pose a significant danger, it is water that typically cripples business operations long-term. As demonstrated by Hurricane Harvey, catastrophic flooding from storm surge and torrential rain causes the most lasting damage and financial loss. Many businesses prepare for wind but lack a contingency for significant inundation, which can destroy inventory, ruin mission-critical equipment, and render facilities unusable for months. A thorough risk assessment must quantify the threat of water.

An effective operational plan moves beyond just surviving high winds. It must quantify and mitigate the specific risks posed by storm surge and inland flooding, which often cause the most significant long-term damage to facilities and supply chains.

We're Far Inland. Do We Really Need a Hurricane Plan?

Yes. A major hurricane is a regional event, with cascading impacts that disrupt operations hundreds of miles from the coast. Even if a facility is not exposed to storm surge, the business remains vulnerable.

Consider the inland threats from a decaying hurricane:

- Destructive winds and tornadoes that can form with little warning.

- Widespread power outages affecting entire regions for days.

- Severe inland flooding from extreme rainfall that paralyzes transportation networks.

Furthermore, even if a facility is undamaged, the supply chain, workforce, and customer base may be located in hard-hit coastal areas. A robust plan must account for these indirect impacts. True resilience requires preparing for the storm's total effect on the entire operational ecosystem.

At ClimateRiskNow, we translate complex meteorology into clear, actionable intelligence for your business. Our Sentinel Shield assessments provide the facility-specific, data-driven insights that Texas businesses in the Energy, Manufacturing, Logistics, and Construction sectors need to protect assets, make informed resilience investments, and maintain operational continuity. Move from guessing about your climate risk to knowing it.